Product Description

Elite GFT Travel Drives are unsurpassed by any crawler or milling machines. Thanks to compact, rugged design, high torque and load capabilities, and optional mechanical lifetime seals, these solutions are the best possible option for the machine. All units are available with a fail-safe parking brake and most have the option of cartridge type fixed or variable systems.

Features:

Compact structure and space-saving design

Robust main bearing system

High torque capacity

High load capacity

Integrated static multiple disk parking brake

Optional Disconnect device for towing

Optional Quick disconnection device

Simple mounting

Easy oil change

Low-noise running operation

Specifications:

| Model | HFT070T |

| Max. output torque: | 70000 NM |

| Rated. output torque: | 56000NM |

| Input speed |

up to 3,600 rpm |

| Ratio: | 35 |

| Static Brake Torque | ≥60000NM ;Spring brake, multi-disc service brakes |

| Dynamic Loading: | 688KN |

| Static Loading: | 1520KN |

| Applicable motors: | Cartridge axial piston hydraulic motors Flanged axial piston hydraulic motors Hydraulic orbit motors Electrical motors

|

| Application: | Travel for Track, Chain and Wheel driving machines ; for example bulldozer,Crawler excavator,Bracket Truck |

In conclusion, ELITE Hydraulic offers quality, value, and professional power transmission solutions that cater to a wide variety of industries. With their expertise, experience, and commitment to customer satisfaction, you can be sure that you’re in safe hands when working with them. Whether you need travel gearbox, electrical drive, travel drive,slew gearbox,winche gearbox,cutter gearbox,truck mixer gearbox,twin shaft mixer or other hydraulic transmission solutions, you can trust ELITE Hydraulic to provide you with the best possible solutions. Contact them today to learn more about their power transmission products and services.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Motorcycle, Machinery, Agricultural Machinery |

|---|---|

| Function: | Change Drive Torque, Speed Changing, Speed Reduction |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Double-Step |

| Type: | Planetary Gear Box |

| Customization: |

Available

| Customized Request |

|---|

Smooth and Controlled Movement in Industrial Robots with Planetary Gearboxes

Planetary gearboxes play a crucial role in ensuring smooth and controlled movement in industrial robots, enhancing their precision and performance:

Reduced Backlash: Planetary gearboxes are designed to minimize backlash, which is the amount of play or free movement between gear teeth. This reduction in backlash results in precise and accurate motion control, allowing industrial robots to achieve precise positioning and repeatability.

High Gear Reduction Ratios: Planetary gearboxes offer high gear reduction ratios, allowing the robot’s motor to output higher torque while maintaining lower speed. This capability enables robots to handle heavy loads and perform tasks that require fine adjustments and delicate movements.

Compact Design: The compact and lightweight design of planetary gearboxes allows for their integration into the limited space of industrial robot joints and actuators. This compactness is crucial for maintaining the overall efficiency and agility of the robot’s movements.

Multi-Speed Capabilities: Planetary gearboxes can be designed with multiple gear stages, allowing industrial robots to operate at different speeds as needed for various tasks. This flexibility in speed selection enhances the robot’s versatility in performing tasks of varying complexities.

High Efficiency: Planetary gearboxes are known for their high efficiency, which translates to minimal energy loss during gear transmission. This efficiency ensures that the robot’s movements are smooth and consistent while optimizing energy consumption.

Torque Distribution: The arrangement of planetary gears allows for efficient distribution of torque across multiple gear stages. This feature ensures that the robot’s joints and actuators receive the appropriate amount of torque for controlled movement, even when handling varying loads.

Seamless Integration: Planetary gearboxes are designed to be easily integrated with servo motors and other robotic components. This seamless integration ensures that the gearbox’s performance is harmoniously aligned with the overall robotic system.

Precision and Accuracy: By providing precise gear reduction and motion control, planetary gearboxes enable industrial robots to perform tasks that demand high levels of precision and accuracy, such as assembly, welding, painting, and intricate material handling.

Reduced Vibrations: The reduced backlash and smooth gear engagement in planetary gearboxes contribute to minimized vibrations during robot operation. This results in quieter and more stable robot movements, further enhancing their performance and user experience.

Dynamic Load Handling: Planetary gearboxes can handle dynamic loads that may change during robot operation. Their ability to manage varying loads while maintaining controlled movement is essential for safe and reliable robot performance.

In summary, planetary gearboxes ensure smooth and controlled movement in industrial robots by minimizing backlash, offering high gear reduction ratios, providing a compact design, enabling multi-speed capabilities, maintaining high efficiency, distributing torque effectively, seamlessly integrating with robotic systems, enhancing precision and accuracy, reducing vibrations, and enabling dynamic load handling. These features collectively contribute to the precise and optimized motion of industrial robots in various applications and industries.

Enhancing Wind Turbine System Performance with Planetary Gearboxes

Planetary gearboxes play a crucial role in enhancing the performance and efficiency of wind turbine systems. Here’s how they contribute:

1. Speed Conversion: Wind turbines operate optimally at specific rotational speeds to generate electricity efficiently. Planetary gearboxes allow for speed conversion between the low rotational speed of the wind turbine rotor and the higher speed required by the generator. This speed adaptation ensures the generator operates at its peak efficiency, resulting in maximum power generation.

2. Torque Amplification: Wind turbine blades may experience varying wind speeds, which result in fluctuating torque loads. Planetary gearboxes can amplify the torque generated by the rotor blades before transmitting it to the generator. This torque multiplication helps maintain stable generator operation even during wind speed variations, improving overall energy production.

3. Compact Design: Wind turbines are often installed in locations with limited space, such as offshore platforms or densely populated areas. Planetary gearboxes offer a compact design, allowing for efficient power transmission within a small footprint. This compactness is vital for accommodating gearboxes in the limited nacelle space of the wind turbine.

4. Load Distribution: Wind turbines are subjected to varying wind conditions, including gusts and turbulence. Planetary gearboxes distribute the load evenly among multiple planet gears, reducing stress and wear on individual components. This balanced load distribution improves gearbox durability and reliability.

5. Efficiency Optimization: Planetary gearboxes are known for their high efficiency due to their parallel axis arrangement and multiple gear stages. The efficient power transmission minimizes energy losses within the gearbox, resulting in more power being converted from wind energy to electricity.

6. Maintenance and Reliability: The robust construction of planetary gearboxes contributes to their durability and longevity. Wind turbines often operate in challenging environments, and the reliability of the gearbox is crucial for minimizing maintenance and downtime. Planetary gearboxes’ low maintenance requirements and ability to handle varying loads contribute to the overall reliability of wind turbine systems.

7. Variable Speed Control: Some wind turbines use variable-speed operation to optimize power generation across a range of wind speeds. Planetary gearboxes can facilitate variable speed control by adjusting the gear ratio to match the wind conditions. This flexibility improves energy capture and reduces stress on turbine components.

8. Adaptation to Turbine Size: Planetary gearboxes are available in various sizes and gear ratios, making them adaptable to different turbine sizes and power outputs. This versatility allows wind turbine manufacturers to select gearboxes that align with specific project requirements.

Overall, planetary gearboxes play a pivotal role in optimizing the performance, efficiency, and reliability of wind turbine systems. Their ability to convert speed, amplify torque, and distribute loads makes them a key component in harnessing wind energy for clean and sustainable electricity generation.

Role of Sun, Planet, and Ring Gears in Planetary Gearboxes

The arrangement of sun, planet, and ring gears is a fundamental aspect of planetary gearboxes and significantly contributes to their performance. Each gear type plays a specific role in the gearbox’s operation:

- Sun Gear: The sun gear is located at the center and is driven by the input power source. It transmits torque to the planet gears, causing them to orbit around it. The sun gear’s size and rotation speed affect the overall gear ratio of the system.

- Planet Gears: Planet gears are smaller gears that surround the sun gear. They are held in place by the planet carrier and mesh with both the sun gear and the internal teeth of the ring gear. As the sun gear rotates, the planet gears revolve around it, engaging with both the sun and ring gears simultaneously. This arrangement multiplies torque and changes the direction of rotation.

- Ring Gear (Annulus Gear): The ring gear is the outermost gear with internal teeth that mesh with the planet gears’ external teeth. It remains stationary or acts as the output shaft. The interaction between the planet gears and the ring gear causes the planet gears to rotate on their own axes as they orbit the sun gear.

The arrangement of these gears allows for various gear reduction ratios and torque multiplication effects, making planetary gearboxes versatile and efficient for a wide range of applications. The combination of multiple gear engagements and interactions distributes the load across multiple gear teeth, resulting in higher torque capacity, smoother operation, and lower stress on individual gear teeth.

Planetary gearboxes offer advantages such as compact size, high torque density, and the ability to achieve multiple gear reduction stages within a single unit. The arrangement of the sun, planet, and ring gears is essential for achieving these benefits while maintaining efficiency and reliability in various mechanical systems.

editor by CX 2024-04-22

China Best Sales 115 mm Good Service CZPT box Small Spur Precision Planetary Gearbox with Good quality

Product Description

Detailed Photos

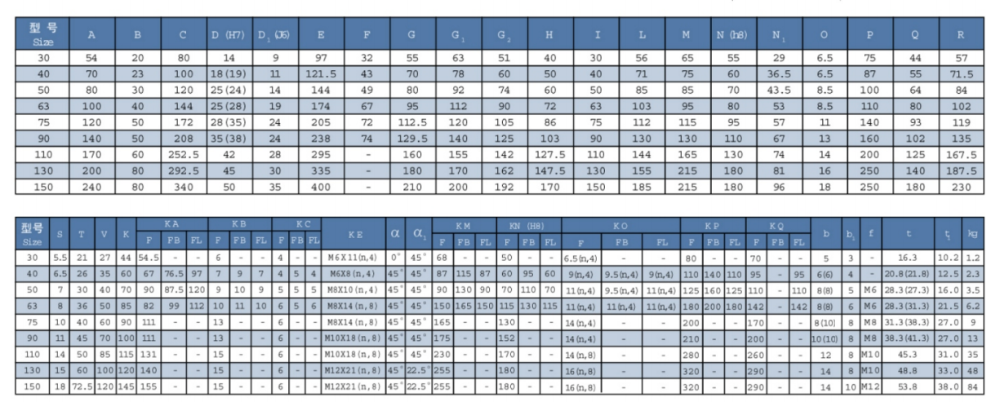

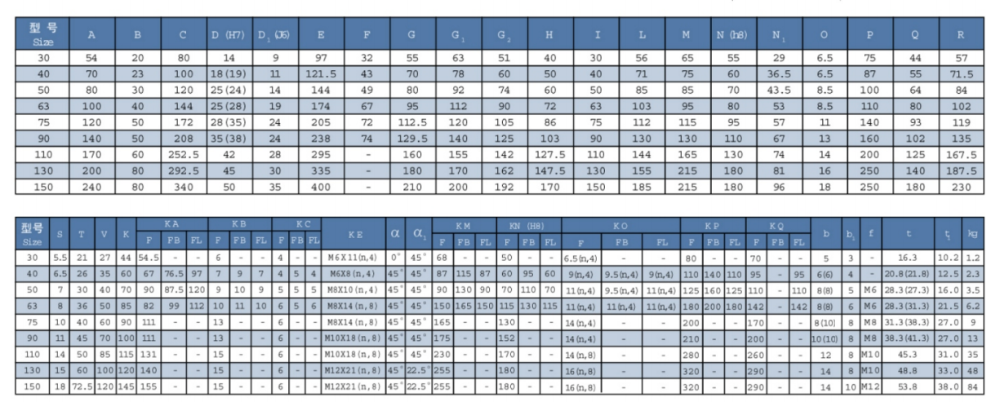

Product Parameters

Note : It’s just the typical technical data for you reference, The specification such as voltage, speed, torque, shaft can be customized by your needs. Please contact us for more details. Thanks.

Company Profile

FAQ

Q: What’re your main products?

A: We currently produce Brushed Dc Motors, Brushed Dc Gear Motors, Planetary Dc Gear Motors, Brushless Dc Motors, Stepper motors, Ac Motors and High Precision Planetary Gear Box etc. You can check the specifications for above motors on our website and you can email us to recommend needed motors per your specification too.

Q: How to select a suitable motor?

A:If you have motor pictures or drawings to show us, or you have detailed specs like voltage, speed, torque, motor size, working mode of the motor, needed lifetime and noise level etc, please do not hesitate to let us know, then we can recommend suitable motor per your request accordingly.

Q: Do you have a customized service for your standard motors?

A: Yes, we can customize per your request for the voltage, speed, torque and shaft size/shape. If you need additional wires/cables soldered on the terminal or need to add connectors, or capacitors or EMC we can make it too.

Q: Do you have an individual design service for motors?

A: Yes, we would like to design motors individually for our customers, but it may need some mold developing cost and design charge.

Q: What’s your lead time?

A: Generally speaking, our regular standard product will need 15-30days, a bit longer for customized products. But we are very flexible on the lead time, it will depend on the specific orders.

Please contact us if you have detailed requests, thank you ! /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery |

|---|---|

| Function: | Speed Changing, Speed Reduction |

| Layout: | Cycloidal |

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Step: | Three-Step |

| Customization: |

Available

| Customized Request |

|---|

Concept of Coaxial and Parallel Shaft Arrangements in Planetary Gearboxes

Coaxial and parallel shaft arrangements refer to the orientation of the input and output shafts in a planetary gearbox:

- Coaxial Shaft Arrangement: In this arrangement, the input and output shafts are aligned along the same axis, with one shaft passing through the center of the other. This design results in a compact and space-efficient gearbox, making it suitable for applications with limited space. Coaxial planetary gearboxes are commonly used in scenarios where the gearbox needs to be integrated into a compact housing or enclosure.

- Parallel Shaft Arrangement: In a parallel shaft arrangement, the input and output shafts are positioned parallel to each other but not on the same axis. Instead, they are offset from each other. This configuration allows for greater flexibility in designing the layout of the gearbox and the surrounding machinery. Parallel shaft planetary gearboxes are often used in applications where the spatial arrangement requires the input and output shafts to be positioned in different locations.

The choice between a coaxial and parallel shaft arrangement depends on factors such as available space, mechanical requirements, and the desired layout of the overall system. Coaxial arrangements are advantageous when space is limited, while parallel arrangements offer more design flexibility for accommodating various spatial constraints.

Differences Between Inline and Right-Angle Planetary Gearbox Configurations

Inline and right-angle planetary gearbox configurations are two common designs with distinct characteristics suited for various applications. Here’s a comparison of these configurations:

Inline Planetary Gearbox:

- Configuration: In an inline configuration, the input and output shafts are aligned along the same axis. The sun gear, planetary gears, and ring gear are typically arranged in a straight line.

- Compactness: Inline gearboxes are more compact and have a smaller footprint, making them suitable for applications with limited space.

- Efficiency: Inline configurations tend to have slightly higher efficiency due to the direct alignment of components.

- Output Speed and Torque: Inline gearboxes are better suited for applications that require higher output speeds and lower torque.

- Applications: They are commonly used in robotics, conveyors, printing machines, and other applications where space is a consideration.

Right-Angle Planetary Gearbox:

- Configuration: In a right-angle configuration, the input and output shafts are oriented at a 90-degree angle to each other. This allows for a change in direction of power transmission.

- Space Flexibility: Right-angle gearboxes offer flexibility in arranging components, making them suitable for applications that require changes in direction or where space constraints prevent a straight-line configuration.

- Torque Capacity: Right-angle configurations can handle higher torque loads due to the increased surface area of gear engagement.

- Applications: They are often used in cranes, elevators, conveyor systems, and applications requiring a change in direction.

- Efficiency: Right-angle configurations may have slightly lower efficiency due to increased gear meshing complexity and potential for additional losses.

Choosing between inline and right-angle configurations depends on factors such as available space, required torque and speed, and the need for changes in power transmission direction. Each configuration offers distinct advantages based on the specific needs of the application.

Contribution of Planetary Gearboxes to Efficient Industrial Automation and Robotics

Planetary gearboxes play a crucial role in enhancing the efficiency of industrial automation and robotics systems by offering several advantages:

1. Compact Design: Planetary gearboxes provide high power density and a compact form factor. This is essential in robotics and automation where space is limited and components need to be tightly integrated.

2. High Torque Density: Planetary gearboxes can achieve high torque output in a compact size, allowing robots and automated systems to handle heavy loads and perform demanding tasks efficiently.

3. Precision and Accuracy: The design of planetary gear systems ensures accurate and precise motion control. This is vital in robotics applications where precise positioning and smooth movement are required for tasks such as pick-and-place operations and assembly.

4. Redundancy: Some planetary gearboxes feature multiple stages and redundant configurations. This provides a level of built-in redundancy, enhancing the reliability of automation systems by allowing continued operation even if one stage fails.

5. Efficiency: Planetary gearboxes are designed for high efficiency, minimizing energy losses and ensuring that the power delivered to the output stage is effectively utilized. This efficiency is crucial for reducing energy consumption and optimizing battery life in robotic applications.

6. Speed Control: Planetary gearboxes allow for precise speed control, enabling robots to perform tasks at varying speeds as needed. This flexibility is essential for tasks that require different motion dynamics or speed profiles.

7. Reduction of Motor Loads: Planetary gearboxes can reduce the load on the motor by providing mechanical advantage through gear reduction. This allows smaller, more efficient motors to be used without sacrificing performance.

8. Shock Absorption: The inherent elasticity of gear teeth in planetary gearboxes can help absorb shocks and impacts, protecting the system components and ensuring smooth operation in dynamic environments.

9. Customization: Planetary gearboxes can be tailored to specific application requirements, including gear ratios, output configurations, and mounting options. This adaptability allows for optimal integration into various automation and robotics setups.

10. Maintenance and Durability: High-quality planetary gearboxes are designed for durability and low maintenance. This is especially important in industrial automation and robotics, where continuous operation and minimal downtime are essential.

Overall, planetary gearboxes contribute significantly to the efficient operation of industrial automation and robotics systems by providing the necessary torque, precision, compactness, and reliability required for these dynamic and demanding applications.

editor by CX 2024-04-04

China manufacturer & factory supplier for Chinese in Mashhad Iran Supplier RV Aluminium Gearbox Speed Reducer With high quality best price & service

Competence for industrial chains and sprockets It is our day-to-day problem to provide our buyers with the best item – that indicates ideal for the necessary software and for the customers’ particular requirements. In some instances it means that we really build and manufacture very specific chain sorts for 1 certain consumer. In purchase to be capable to do so, a few issues are crucial:Total use has been produced of all varieties of innovative methods and technology to achieve excelsior manufacturing.

Overview

Fast Particulars

- Relevant Industries:

-

AT collection with tri-lobe tube (triangular) The triangular tube condition is the most utilized, from light-weight to reasonably heavy programs. In the scenario of apps with high sliding, the R version with Rilsan coating is also accessible. AL collection with two-lobe tubes (lemon).

Creating Content Stores, Manufacturing Plant, Equipment Mend Stores

-

EPG Machinery is situated in XiHu Area HangZhou Zhejiang ,China. It is 30km from our manufacturing unit to HangZhou global airport.

- Gearing Arrangement:

-

Worm

- Output Torque:

-

2.6-1195N.m

- Enter Velocity:

-

1400r/min

- Output Velocity:

-

23.3-186.7r/min

- Place of Origin:Zhejiang, China

- Manufacturer Name:

-

OEM

- Design Variety:

-

NMRV

- Rated Electricity:

-

.06-15KW

- Merchandise Name:

-

Chinese Provider RV Aluminium Gearbox Pace Reducer

- Body Substance:

-

Aluminium Alloy or Cast Iron Housing

- Worm Shaft Material:

-

Carburizing Metal, 20CrMnTi, fifty eight-62HRC

- Worm Wheel:

-

Bronze Alloy

- Bearing Brand name:

-

NSK, C&U

- Lubricant:

-

Worm Equipment reducers are utilized in electricity transmission programs demanding substantial ratio speed reduction in a minimal room. The gears are employed on proper angle, non-intersecting shafts. When effectively aligned, worms and worm gears are the quietest and smoothest kind of gearing. One drawback of worm gearing is as the ratio of this gearing boost, the performance of the gearing decreases. A worm equipment reducer is a right angle speed reducer that enables the highest speed reduction in the smallest deal.

Artificial or Mineral Lubrication Oil

- Certificate:

-

CE ISO9001

- Warranty:

-

12 Months

Source Potential

- Source Potential:

- a million Piece/Pieces for every Month

Packaging & Delivery

- Packaging Details

- Regular export packing and wooden pallets packing

- Port

- Shanghai or Ningbo Port

On the web Customization

Merchandise Description

RV Aluminium Gearbox Velocity Reducer, mounting proportions can interchangeable with MOTOVARIO.

one. Created of higher-quality aluminium alloy, mild bodyweight and non-rusting

two. Massive output torque

three. Clean running and reduced sound

4. Higher radiating efficiency

5. Great-hunting appearance, durable provider existence and small volume

six. Appropriate for omni-bearing set up.

In depth Photos

Detailed Images of RV Aluminium Gearbox Speed Reducer

Packing & Supply

Packing Images of RV Aluminium Gearbox Speed Reducer

Inner Packing: PP bag with carton

Outer Packing: Wood scenario

Shipment: fourteen-twenty times upon getting the deposit.

About Us

Ever_electrical power Team is the initial and largest worm gearbox maker in China, set up in 1976, specialising in the generation of a broad variety of transmission equipment. With more than 40 years knowledge in the business, our belongings now total 117.2 million bucks, and we have 2 subsidiary businesses, 8 keeping businesses, and twelve joint-stock companies.

We can generate four hundred,000 units of worm gearboxes, a hundred,000 units of equipment reducers, fifty,000 units of other speed reducers, one hundred fifty,000 models of flexible couplings, and 100,000 models of speed-reducer components each calendar year.

70% of our merchandise have been exported to forty much more international locations, and our buyers occur from Italy, Germany, United states, Canada, Spain, British isles, India, Mexico, Brazil, Argentina, Turkey, Singapore and other main industrial nations around the world. 30% of them are OEM produced for direct producers of other goods.

FAQ

Q1. Is your high quality great?

A1: Quality never inform lies, we’re the biggest company and exporter of worm gear reducer in Asia, the very first reducers and gearboxes producer in China, who has been provided license because 1993. Also, we experienced achieved ISO9001 and CE Certification between all producers.

Q2. How is your cost? Can you supply any price cut?

A2: We will give the ideal value we can foundation on your demands and the portions.

Q3. Do you offer any browsing?

A3: Sure! We sincerely invite you to visit us! We can pick you from airport, railway station and so on. Also, we can organize housing for you. Make sure you let us know in innovative.

This fall. When is the ideal time to contact you?

A4: You can speak to us by e mail any time, we will reply you ASAP. If you want speak to by telephone, our working hour is Mon-Sat 9am-17:30pm.

Get in touch with

Ever_power Group

Handle: No.789-B8Shenhua Road, XiHu Dsitriction Enco&Tech Growth Zone HangZhou Metropolis, ZJ, P.R.

Tel: 0086-571-88220971/Mob: +86 13083988828

WhatsApp/Skype: +86 13083988828

Site: www.hzpt.com