Product Description

Overview

Product Description

Wide Selection of Gearbox Products

The gearbox usually adopts a general design scheme, but in special cases, the design scheme of the gearbox can be changed according to the demands of the user, and it can be modified into an industry-specific gearbox. In the design scheme of the gearbox, the parallel shaft, vertical shaft, general box, and various parts can be changed

Advantages

- Absorption of very high torques and axial forces

- No need for separate thrust housing & bearing.

- Easy alignment (screw directly fits into the vore of gear box)

- Easy to assemble & dismantle.

- Very heavy duty spherical roller thrust bearing is provided.

- Power saving. (you may save up to 20 % power.)

- Less requirement of space.

- For bigger sizes water cooling is provided

- No maintenance required except periodic oil level checking.

- Higher productivity

Features

- Twin Screw Extruder Gearboxes offer the dual shaft counter rotating. The range is available for various center distances

- The gearboxes are available with co-rotating and counter rotating variants

- To work under heavy loading force, the high level dissipation and oil lubrication system are provided. The axial roller type swivel thrust with the thrust bearing coupled in tandem way support the axial thrust

- High torque and high speed output rate

Processing Characteristics of Screw Shaft:

1.Suitable suggestion on material to ensure components performance and extend lifetime of products.

2.Professional technical team can provide surveying and mapping support.

3.All components are finished by CNC machine.

4.Sophisticated quality management system ensure superior quality.

Basic Info.

| Warranty: 1 year | Weight (KG): 500 KG |

| Place of Origin: HangZhou, China |

Gearing Arrangement: helical |

| ratio: 8-20 |

Output Torque: 2*176 |

| standard: JB/T8853-2001 |

Certificate: CE |

| Heat treatment: High-frequency Hardening |

Efficiency: 94%~98%(depends on the transmission stage) |

| Customized support:OEM ODM | Input/output shaft material 40Cr |

| Package: Wooden case |

Mount position: Flange, hollow shaft, CZPT shaft |

| After-sale:Online 24/7 Installation Xihu (West Lake) Dis. | advantage: excellent quality |

| Reduction radio: 3:1 |

Mount Position: Horizontal Foot Mounted Vertical |

| Input Speed: 1500 |

Output Speed: 500 |

Packaging & delivery

|

Packing: wooden case packing |

|

| Port: HangZhou Port |

Applications

X helical gear units for double-screw extruders with parallel drive shafts and the same direction of screw rotation are used mainly in the manufacture of granulates and the refining of raw plastics. Other areas of application include:

- Paint and lacquer industry

- Washing agent industry

- Foodstuff industry (e.g. bread, pasta)

- Animal-feed industry (dog, cat other animal food

Maintenance of the gearbox of the dual-screw extruder

1. The gear box of the dual-screw extruder should be well-ventilated, and the working environment temperature should be within the range of 5-35 °C.

2. Always check the oil quantity of the gear lubricating oil in the box to ensure that the transmission parts in the box are well lubricated.

3. Pay attention to check the bearing parts of the box frequently. The oil temperature of the oil tank of the transmission box should not exceed 70 ºC during operation.

4. The newly put into use gearbox needs to replace the lubricating oil after 250 hours of operation. The oil change time depends on the state of the oil. It is recommended to replace it after 4000-8000 hours of operation or once a year.

5. The gearbox of the dual-screw extruder needs to be regularly maintained and inspected once a year

Operating Process

1. The gear on the input shaft is driven by the motor and starts to rotate.

2. The rotating input gear meshes with other gears inside the gearbox, transmitting power.

3. Different-sized gears within the gearbox are combined to form a gear train. Through continuous meshing and rotation, the high-speed, low-torque power from the input shaft gradually converts into low-speed, high-torque output.

4. The output shaft is connected to the last gear and transfers the output torque to the load.

5. Gear reduction gearboxes typically include lubrication and cooling systems to ensure smooth operation and prevent overheating and damage.

6. Our extruder gearbox converts high-speed, low-torque power into low-speed, high-torque output by changing the size ratios and meshing arrangements of different gears, achieving the function of speed reduction.

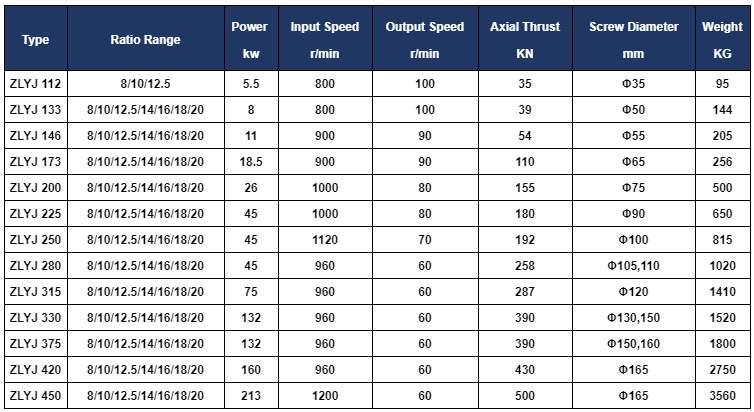

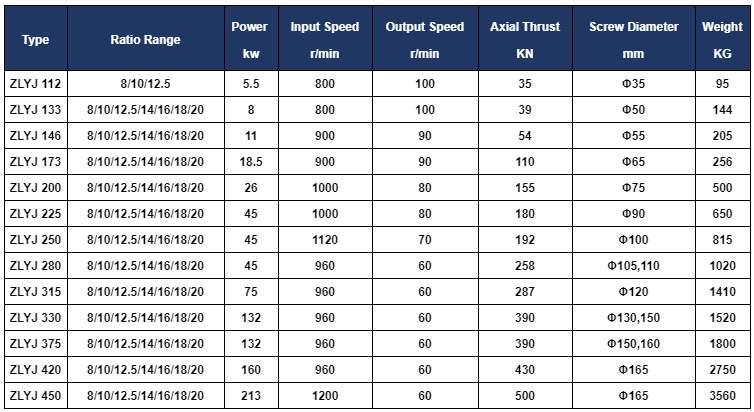

Types of Gearboxes:

Based on customer requirements, gear reduction gearboxes can be classified according to the size of the output shaft, center distance of the output shaft, output speed, and torque. Alternatively, we can provide several commonly used types of gearboxes for customers to choose from.

Product Service

|

24-hour Hotline

No matter when and where to call we can find our service to you.

|

Pre-sales Consultation

We have 5 sales people online, and whether you have any question can be solved through online communication. |

After-sales Services

Receive products have any questions about the product, can look for us,we will help you deal with the the first time,to your satisfaction. |

Exhibition

Certificate

Company profile

ZheJiang Arrow Machinery Co., Ltd.is a company specializing in R&D, production, sales, application promotion of food engineering projects. As 1 of the largest scaled food processing equipment &whole plant engineering problem solvers in China, machines served for more than 970 companies, export to 116 countries, area, more than 20 years engineering team, we recognize that quality equals value, aims to create a great future together with global customers.

FAQ

1. Q: How about Arrow Machinery?

R: ZheJiang Arrow Machinery Co., Ltd. is a High-Tech company. Our firm is composed of a strong

team which has substantial experience in R&D, manufacture, technique and sales service and has

specialized in extruder industry for 10 years,leading screw barrel manufacturer in China.

2. Q:What’s Arrow machinery’s capacity?

R:Company is in strict accordance with CE and ISO9001 quality certification system.There are over 200

models of extruders and spare parts.

3. Q:What’s the delivery time?

R:For regular size, we have finished stock and semi-finished stock, 2 weeks max enough

for customized, normally within 20days .

4. Q:How about the gearbox quality and price?

R: top quality in China with competitive price and globle after-sale service

5. Q:what’s the life time and guarantee buy from Arrow machinery ?

R: 3~5years life time for nitriding ones and bimtallic ones will be longer

One year min. Guarantee.

6.Q:Where is Arrow Machinery factory and how to reach there?

R:NO.47 Chengbohu Road, Xihu (West Lake) Dis. District,HangZhou City, China. You can take the train or plane to HangZhou and we can pick you up.

7.Q:How to contact with you?

R:just reply to me if have any question.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Cycloidal |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Challenges in Achieving High Gear Ratios with Compactness in Planetary Gearboxes

Designing planetary gearboxes with high gear ratios while maintaining a compact form factor poses several challenges due to the intricate arrangement of gears and the need to balance various factors:

Space Constraints: Increasing the gear ratio typically requires adding more planetary stages, resulting in additional gears and components. However, limited available space can make it challenging to fit these additional components without compromising the compactness of the gearbox.

Efficiency: As the number of planetary stages increases to achieve higher gear ratios, there can be a trade-off in terms of efficiency. Additional gear meshings and friction losses can lead to decreased overall efficiency, impacting the gearbox’s performance.

Load Distribution: The distribution of loads across multiple stages becomes critical when designing high gear ratio planetary gearboxes. Proper load distribution ensures that each stage shares the load proportionally, preventing premature wear and ensuring reliable operation.

Bearing Arrangement: Accommodating multiple stages of planetary gears requires an effective bearing arrangement to support the rotating components. Improper bearing selection or arrangement can lead to increased friction, reduced efficiency, and potential failures.

Manufacturing Tolerances: Achieving high gear ratios demands tight manufacturing tolerances to ensure accurate gear tooth profiles and precise gear meshing. Any deviations can result in noise, vibration, and reduced performance.

Lubrication: Adequate lubrication becomes crucial in maintaining smooth operation and reducing friction as gear ratios increase. However, proper lubrication distribution across multiple stages can be challenging, impacting efficiency and longevity.

Noise and Vibration: The complexity of high gear ratio planetary gearboxes can lead to increased noise and vibration levels due to the higher number of gear meshing interactions. Managing noise and vibration becomes essential for ensuring acceptable performance and user comfort.

To address these challenges, engineers employ advanced design techniques, high-precision manufacturing processes, specialized materials, innovative bearing arrangements, and optimized lubrication strategies. Achieving the right balance between high gear ratios and compactness involves careful consideration of these factors to ensure the gearbox’s reliability, efficiency, and performance.

Impact of Temperature Variations and Environmental Conditions on Planetary Gearbox Performance

The performance of planetary gearboxes can be significantly influenced by temperature variations and environmental conditions. Here’s how these factors impact their operation:

Temperature Variations: Extreme temperature fluctuations can affect the lubrication properties of the gearbox. Cold temperatures can cause the lubricant to thicken, leading to increased friction and reduced efficiency. On the other hand, high temperatures can cause the lubricant to thin out, potentially leading to insufficient lubrication and accelerated wear.

Environmental Contaminants: Planetary gearboxes used in outdoor or industrial environments can be exposed to contaminants such as dust, dirt, moisture, and chemicals. These contaminants can infiltrate the gearbox and degrade the quality of the lubricant. Additionally, abrasive particles can cause wear on gear surfaces, leading to decreased performance and potential damage.

Corrosion: Exposure to moisture, especially in humid or corrosive environments, can lead to corrosion of gearbox components. Corrosion weakens the structural integrity of gears and other components, which can ultimately result in premature failure.

Thermal Expansion: Temperature changes can cause materials to expand and contract. In gearboxes, this can lead to misalignment of gears and improper meshing, causing noise, vibration, and reduced efficiency. Proper consideration of thermal expansion is crucial in gearbox design.

Sealing and Ventilation: To mitigate the impact of temperature and environmental factors, planetary gearboxes need effective sealing to prevent contaminants from entering and to retain the lubricant. Proper ventilation is also essential to prevent pressure build-up inside the gearbox due to temperature changes.

Cooling Systems: In applications where temperature control is critical, cooling systems such as fans or heat exchangers can be incorporated to maintain optimal operating temperatures. This helps prevent overheating and ensures consistent gearbox performance.

Overall, temperature variations and environmental conditions can have a profound impact on the performance and lifespan of planetary gearboxes. Manufacturers and operators need to consider these factors during design, installation, and maintenance to ensure reliable and efficient operation.

Role of Sun, Planet, and Ring Gears in Planetary Gearboxes

The arrangement of sun, planet, and ring gears is a fundamental aspect of planetary gearboxes and significantly contributes to their performance. Each gear type plays a specific role in the gearbox’s operation:

- Sun Gear: The sun gear is located at the center and is driven by the input power source. It transmits torque to the planet gears, causing them to orbit around it. The sun gear’s size and rotation speed affect the overall gear ratio of the system.

- Planet Gears: Planet gears are smaller gears that surround the sun gear. They are held in place by the planet carrier and mesh with both the sun gear and the internal teeth of the ring gear. As the sun gear rotates, the planet gears revolve around it, engaging with both the sun and ring gears simultaneously. This arrangement multiplies torque and changes the direction of rotation.

- Ring Gear (Annulus Gear): The ring gear is the outermost gear with internal teeth that mesh with the planet gears’ external teeth. It remains stationary or acts as the output shaft. The interaction between the planet gears and the ring gear causes the planet gears to rotate on their own axes as they orbit the sun gear.

The arrangement of these gears allows for various gear reduction ratios and torque multiplication effects, making planetary gearboxes versatile and efficient for a wide range of applications. The combination of multiple gear engagements and interactions distributes the load across multiple gear teeth, resulting in higher torque capacity, smoother operation, and lower stress on individual gear teeth.

Planetary gearboxes offer advantages such as compact size, high torque density, and the ability to achieve multiple gear reduction stages within a single unit. The arrangement of the sun, planet, and ring gears is essential for achieving these benefits while maintaining efficiency and reliability in various mechanical systems.

editor by CX 2024-04-09

China Good quality CZPT Micro Planetary Plastic Gearbox 8mm RC Car Gear Box of Car application of planetary gearbox

Product Description

Product Description

Model: ZWBMD006006-711

Rated Voltage: 3V

No Load Speed: 26rpm

No load current: 40mA

Rated Speed: 22rpm

Rated Current: 100mA

Rated Torque: 296.9g.cm

Overall Length : 30.9mm

Rated Torque of Gear Box: 330g.cm

Instant Torque of Gear Box: 800g.cm

Gear Ratio: 711:1

Gear Box Length: 16.9mm

Specifications:

| Model | Application Parameters | Rated Torque of Gear Box | Instant Torque of Gear Box | Gear Ratio | Gear Box Length L1 |

|||||||

| Rated | At No Load | At Rated Load | Overall Length L |

|||||||||

| Voltage | Speed | Current | Speed | Current | Torque | |||||||

| VDC | rpm | mA | rpm | mA | gf.cm | mN.m | mm | gf.cm | gf.cm | mm | ||

| ZWBMD006006-110 | 3.0 | 166 | 37 | 140 | 100 | 54.3 | 5.33 | 28.5 | 330 | 800 | 110.6 | 14.5 |

| ZWBMD006006-148 | 3.0 | 124 | 37 | 105 | 100 | 72.8 | 7.14 | 28.5 | 330 | 800 | 148.1 | 14.5 |

| ZWBMD006006-198 | 3.0 | 93 | 37 | 78 | 100 | 97.5 | 9.56 | 28.5 | 330 | 800 | 198.4 | 14.5 |

| ZWBMD006006-266 | 3.0 | 69 | 37 | 58 | 100 | 130.5 | 12.80 | 28.5 | 330 | 800 | 265.7 | 14.5 |

| ZWBMD006006-531 | 3.0 | 35 | 40 | 29 | 100 | 221.7 | 21.74 | 30.9 | 330 | 800 | 530.8 | 16.9 |

| ZWBMD006006-711 | 3.0 | 26 | 40 | 21 | 100 | 296.9 | 29.12 | 30.9 | 330 | 800 | 711.0 | 16.9 |

| ZWBMD006006-952 | 3.0 | 19 | 40 | 16 | 95 | 330 | 32.36 | 30.9 | 330 | 800 | 952.2 | 16.9 |

| ZWBMD006006-1275 | 3.0 | 14 | 40 | 12 | 85 | 330 | 32.36 | 30.9 | 330 | 800 | 1275.2 | 16.9 |

| ZWBMD006006-1708 | 3.0 | 11 | 40 | 10 | 75 | 330 | 32.36 | 30.9 | 330 | 800 | 1707.9 | 16.9 |

above specifications just for reference and customizable according to requirements.

Please let us know your requirements and we will provide you with micro transmission solutions.

2D Drawing

Detailed Photos

Application

| Smart wearable devices | watch,VR,AR,XR and etc. |

| Household application | kitchen appliances, sewing machines, corn popper, vacuum cleaner, garden tool, sanitary ware, window curtain, intelligent closestool, sweeping robot, power seat, standing desk, electric sofa, TV, computer, treadmill, spyhole, cooker hood, electric drawer, electric mosquito net, intelligent cupboard, intelligent wardrobe, automatic soap dispenser, UV baby bottle sterilizer, lifting hot pot cookware, dishwasher, washing machine, food breaking machine, dryer, air conditioning, dustbin, coffee machine, whisk,smart lock,bread maker,Window cleaning robot and etc. |

| communication equipment | 5G base station,video conference,mobile phone and etc. |

| Office automation equipments | scanners, printers, multifunction machines copy machines, fax (FAX paper cutter), computer peripheral, bank machine, screen, lifting socket, display,notebook PC and etc. |

| Automotive products | conditioning damper actuator, car DVD,door lock actuator, retractable rearview mirror, meters, optic axis control device, head light beam level adjuster, car water pump, car antenna, lumbar support, EPB, car tail gate electric putter, HUD, head-up display, vehicle sunroof, EPS, AGS, car window, head restraint, E-booster, car seat, vehicle charging station and etc. |

| Toys and models | radio control model, automatic cruise control, ride-on toy, educational robot, programming robot, medical robot, automatic feeder, intelligent building blocks, escort robot and etc. |

| Medical equipments | blood pressure meter, breath machine, medical cleaning pump, medical bed, blood pressure monitors, medical ventilator, surgical staplers, infusion pump, dental instrument, self-clotting cutter, wound cleaning pump for orthopedic surgery,electronic cigarette, eyebrow pencil,fascia gun, , surgical robot,laboratory automation and etc. |

| Industrials | flow control valves, seismic testing,automatic reclosing,Agricultural unmanned aerial vehicle,automatic feeder ,intelligent express cabinet and etc. |

| Electric power tools | electric drill, screwdriver,garden tool and etc. |

| Precision instruments | optics instruments,automatic vending machine, wire-stripping machine and etc. |

| Personal care | tooth brush, hair clipper, electric shaver, massager, vibrator, hair dryer, rubdown machine, scissor hair machine, foot grinder,anti-myopia pen, facial beauty equipment, hair curler,Electric threading knife,POWER PERFECT PORE, Puff machine,eyebrow tweezers and etc. |

| Consumer electronics | camera, mobile phone,digital camera, automatic retracting device,camcorder, kinescope DVD,headphone stereo, cassette tape recorder, bluetooth earbud charging case, turntable, tablet,UAV(unmanned aerial vehicle),surveillance camera,PTZ camera, rotating smart speaker and etc. |

| robots | educational robot, programming robot, medical robot, escort robot and etc. |

Company Profile

HangZhou CZPT Machinery & Electronics Co., Ltd was established in 2001,We provide the total drive solution for customers from design, tooling fabrication, components manufacturing and assembly.

Workshop

Testing Equipment

1) Competitive Advantages

- 1) Competitive Advantages

19+year experience in manufacturing motor gearbox

We provide technical support from r&d, prototype, testing, assembly and serial production , ODM &OEM

Competitive Price

Product Performance: Low noise, High efficiency, Long lifespan

Prompt Delivery: 15 working days after payment

Small Orders Accepted

2) Main Products

-

Precision reduction gearbox and its diameter:3.4mm-38mm,voltage:1.5-24V,power: 0.01-40W,output speed:5-2000rpm and output torque:1.0 gf.cm -50kgf.cm,

- Customized worm and gear transmission machinery;

- Precise electromechanical motion module;

- Precise component and assembly of plastic and metal powder injection.

Our Services

- ODM & OEM

- Gearbox design and development

- Related technology support

- Micro drive gearbox custom solution

Packaging & Shipping

1) Packing Details

packed in nylon firstly, then carton, and then reinforced with wooden case for outer packing.

Or according to client’s requirement.

2) Shipping Details

samples will be shipped within 10 days;

batch order leading time according to the actual situation.

Certifications

Certifications

We Have passed to hold ISO9001:2015(CN11/3571),ISO14001:2004(U006616E0153R3M), ISO13485:2016(CN18/42018) and IATF16949:2016(CN11/3571.01).

and more…

FAQ

FAQ

1. Can you make the gearbox with custom specifications?

YES. We have design and development team, also a great term of engineers, each of them have

many work years experience.

2.Do you provide the samples?

YES. Our company can provide the samples to you, and the delivery time is about 5-15days according to the specification of gearbox you need.

3.What is your MOQ?

Our MOQ is 2000pcs. But at the beginning of our business, we accept small order.

4. Do you have the item in stock?

I am sorry we donot have the item in stock, All products are made with orders.

5. Do you provide technology support?

YES. Our company have design and development team, we can provide technology support if you

need.

6.How to ship to us?

We will ship the goods to you according to the DHL or UPS or FEDEX etc account you provide.

7.How to pay the money?

We accept T/T in advance. Also we have different bank account for receiving money, like US dollors or RMB etc.

8. How can I know the product is suitable for me?

Frist, you need to provide us the more details information about the product. We will recommend the item to you according to your requirement of specification. After you confirm, we will prepare the samples to you. also we will offer some good advances according to your product use.

9. Can I come to your company to visit?

YES, you can come to our company to visit at anytime, and welcome to visit our company.

10. How do contact us ?

Please send an inquiry

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car, Camera |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase, Micro Gearbox |

| Layout: | Cycloidal |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Samples: |

US$ 90/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Benefits of a Planetary Gearbox With Output Shaft

The output shaft of a Planetary Gearbox connects to the driven wheels, while the input shaft comes from the engine. These gears are interlinked and create a wide range of gear reductions, which are necessary to get a vehicle rolling comfortably. Gear reductions are the place where the various “gears” are located. Here are some examples. They can help you determine what you need for your vehicle. You might also want to learn about planetary gears.

Planetary gearboxes

Modern cars are most likely equipped with planetary gearboxes. If you’re unsure if your vehicle uses planetary gears, you should first consult your car’s owner’s manual. If not, contact your dealership’s service department for more information. Otherwise, you can do a quick search on the internet to find out whether your car has a planetary gearbox. These gearboxes are generally more complex than ordinary gears. Additionally, they are equipped with more parts and require lubrication.

In addition to their low noise levels, planetary gearboxes are also remarkably efficient at transmission. These features make them ideal for applications requiring high torque and small footprints. Unfortunately, there are many different types of planetary gearboxes on the market, making it difficult to find the right one. The following article will give you some guidelines to help you choose the right planetary gearbox for your needs. Let’s take a look!

Planetary gears

A planetary gearbox has two main components: the sun gear (also known as the central or input) and the planet gears (also known as outer or peripheral). These gears are connected together by a carrier to the output shaft of the machine. In some applications, it is necessary to use a planetary gearbox with lubrication to prevent wear and tear. A planetary gearbox also has a small ring gear that helps hold the planet gears together.

The main advantage of a planetary gearbox is that it uses several teeth that engage at once, allowing for high-speed reduction with a small number of gears. Because the gears are relatively small, they have lower inertia than their larger counterparts. Planetary gearboxes are compact, which makes them popular for space-constrained applications. Because of their compact size and efficiency, planetary gearboxes are also commonly used in motor vehicles.

Planetary gearboxes with output shaft

For high-speed, dynamic applications, planetary gearbox units with output shaft provide the optimal solution. Thanks to their low inertia, these gearheads deliver superior performance in many industrial applications. Additionally, their wide range of variants allows users to select the perfect product for their application. This article examines some of the key benefits of planetary gearboxes with output shaft. Read on to learn more.

The planetary gearbox has two major components: a sun gear and planet gears. The sun gear is usually the input gear, while the planet gears are located at the outer edges of the system casing. Planet gears are held together by a carrier that is connected to the output shaft. Before choosing a particular gearbox for your application, make sure that you check the specific requirements and the environment to which the unit will be subjected.

A planetary gearbox has less stages of gears, and thus lower backlash compared to spur gearboxes. Backlash is lost motion that occurs when the teeth of the gears are out of perfect alignment. This problem is common in all gears, but is significantly less in planetary gearboxes. As such, planetary gearboxes are more efficient. They can also be customized according to the specific engine model and motor flange.

Planetary gearboxes with carrier

A planetary gearbox is a type of gearbox with three or more stages. They have a sun gear, which is usually the input gear, and planet gears, also called the outer gears. The carrier that connects the planet gears to the output shaft is called a ring gear. A planetary gearbox is generally designed to meet specific application and environmental requirements, but there are some factors to consider when choosing one.

The compact footprint of planetary gear sets results in high heat dissipation. This can be a problem in applications with sustained performance or high speeds. As a result, planetary gear sets often include lubricants, which present a cooling effect while also reducing noise and vibration. Some planetary gears even feature a carrier to make the installation process easier. Here are some things to keep in mind when choosing a planetary gear set.

Planetary gearboxes with carrier have several advantages over other types of gearboxes. Unlike conventional gearboxes, planetary gears have a common central shaft, and the tangential forces between the gears cancel out at the center of the ring gear. Because of this, planetary gearboxes are commonly used in input/output applications, and their compact size allows for a wide range of gear reductions. These gears can also produce higher torque density.

Planetary gearboxes with traction

Planetary gears are similar to the planetary system, in that each pinion rotates around a sun gear. The output of the planetary gear unit is lower than the drive rotation speed, but the torque is higher. As the number of planet gear wheels increases, so does the torque. Planetary gear systems contain three to four planet gears, and each is in constant mesh with the others. Power applied to any one member rotates the entire assembly.

Typical applications for planetary gear sets include high-precision motion control. In these applications, high torque, torsional stiffness, and low backlash are required. Planetary gear sets are also ideal for motors with higher speeds. A number of factors contribute to the reliability of these devices. The low backlash and large torque capacity of a planetary gear motor allow them to be used in a wide range of applications.

Planetary gearboxes with electric motors

If you’re in the market for a new gearbox, you may have already heard about planetary gearboxes. The planetary gearbox is a high-efficiency, low-noise gearbox. CZPT manufactures high-torque planetary gearboxes with low backlash. They also make economy planetary gearboxes for lower loads. However, with so many different types available, choosing the right one for your needs can be challenging.

These planetary gearboxes are a compact alternative to conventional pinion-and-gear reducers. They offer high-speed reduction and high torque transfer, and are often used for space-constrained applications. But before you can understand how they work, you’ll need to understand a little about their construction. There are a few things to look for that you may not have noticed before.

The most common type of planetary gearbox is a PM81/LN. It features a set of DC brush motors with diameter 77mm, a stator, and two or more outer gears. Each of these gears is connected to an output shaft through a carrier. They can also be used with brakes, encoders, or a clutch. A planetary gearbox is one of the most reliable gearbox types on the market.

Planetary gearboxes with hydraulic motors

A planetary gearbox is a combination of two gears, the sun and the planets. The sun gear rotates at high speed, while the planets roll around and orbit around the ring gear. The output shaft has the same direction of rotation as the input shaft. The benefits of a planetary gearbox include high reduction ratios, efficiency, space-saving compactness, and higher overload capacity. These gears are also more stable and compact, and they do not suffer from self-locking properties.

Planetary gearboxes are a highly efficient way to power hydraulic lifts. They can be input via electric, hydraulic, or air motors. The drive arrangement can be mounted on a bare shaft, splined shaft, or a parallel keyed input shaft. Depending on the application, bespoke gearboxes can be manufactured with a variety of features and functions.

Planetary gearboxes with combustion engines

There are many different applications of planetary gear sets. The most common is the distribution of power between two wheels in a car’s drive axle. Four-wheel drives use two axle differentials, which are further augmented by a centre differential. Hybrid electric vehicles use summation gearboxes to distribute power from the combustion engine to the wheels and to an electric motor. Planetary gear sets also combine the two different types of motors to form one hybrid vehicle.

To understand how planetary gear sets work, it is important to understand the underlying mechanical principles. For example, Fig. 4.6 shows a stick diagram illustrating two planetary gear sets connected by a lever. The two levers are the same length, so the system is analogous to a single lever. When calculating the torque, it is essential to consider the lever diagram. Similarly, if two gear sets are connected by vertical links, the horizontal links must be horizontal.

editor by CX 2023-11-25

China n20 mini dc motor plastic planetary gearbox 6v for lock delta planetary gearbox

Guarantee: Other

Model Number: 12GR120-N20VA

Utilization: Electric Bicycle, Home Equipment, Digital doorway lock ,secure box,toy

Sort: Equipment MOTOR

Torque: 250g.cm

Construction: Long term Magnet

Commutation: Brush

Defend Attribute: Entirely Enclosed

Velocity(RPM): 120rpm

Continuous Current(A): 90mA

Effectiveness: IE 1

Diversion: CW

Gears: Gearbox Reducer

Equipment Sort: Plantary Gearbox

Diameter: 12mm

Key phrases: N20 Equipment Motor

Brush: Precision Metallic

Certification: ce, China ball mill concrete mixer hydraulic motor Angle Gearbox Planetary Equipment Reducer for roller push device RoHS, ISO9001

Packaging Specifics: plastic or foam packing

Motor characteristic example:

| Design | VOLTAGE | NO LOAD | AT Optimum Performance | STALL | ||||||||

| Functioning Selection | RATED | Velocity | Current | Speed | Present | TORQUE | OUTPUT | TORQUE | Existing | |||

| V | r/min | A | r/min | A | mN.m | g.cm | w | mN.m | g.cm | A | ||

| 12GR120-N20VA-10121-3X | two.-4.5 | three | 120 | ninety | ninety five | a hundred and eighty | 4.9 | 50 | .seventeen | 24.nine | 250 | .40 |

| 12GR120-N20VA- 0571 -3X | 1.5-six | six | eighty three | 25 | 65 | 60 | seven.nine | eighty | .15 | 34.9 | 350 | .19 |

| 12GR120-N20VA-1390-3X | two.-7 | 3.7 | 200 | ninety five | one hundred sixty five | 350 | fifteen.9 | 161 | .80 | 89.9 | 900 | 1.ninety five |

Typical applications:

Firm Information

About us

Manufacturing Method

Our Companies Customization support as under are offered

Packaging & Automatic Electrical power Transmission 20mm Tiny Mini Equipment Reducer Planetary Gearbox Pace Reduction for Equipment Motors Transport

FAQ

Q: Are you trading firm or manufacturer ?A: We are manufacturing unit.

Q: How prolonged is your delivery time?A: Typically it is 5-10 times if the items are in stock. or it is twenty-30 times if the goods are not in stock, it is in accordance to amount.

Q: Do you provide samples ? is it free or additional ?A: The sample fee is in accordance to the stock and price.

Q: What is your conditions of payment ?A: Payment=1000USD, H PV collection Higher quality Right Angle Distinctive speed reducer HB helical gearbox gear box thirty% T/T in progress ,stability just before shippment.

The Basics of a Planetary Gearbox

The basic model of a planetary gearbox is a highly efficient transmission that transmits nearly ninety percent of the power it receives. The basic planetary gearbox comes in three basic types: Inline, Helical, and Spur. Below, we will discuss the differences between each of them and which one is better for your needs. A planetary gearbox is an important part of any engine and may be the perfect choice for your vehicle.

Inline planetary gearbox

An inline planetary gearbox has an inline arrangement of gears that enables the transfer of power. Its design makes it stable and reliable, and the space and weight-saving benefits make it a popular choice for many applications. Planetary gearboxes have low inertia, high torque, and a wide range of reduction ratios, which make them a versatile choice for many industries. To find out more about this type of gearbox, read about its construction and specifications.

A planetary gearbox is composed of two parts: a sun gear (also called the central or input gear), and two planet gears (also called outer gears). These gears are connected to each other via a carrier. In order to get the best performance from your gearbox, it’s important to find a model with the features and benefits required for your application. Also, be sure to check out the delivery time, global availability, and customer service of your selected constructor. A few constructors are faster than others and have the ability to respond quickly, while others can deliver every single planetary gearbox out of stock.

Whether you’re using an inline planetary gearbox for your car’s transmission, or you’re building a new machine, it’s important to choose the right size for your application. The most common ratio is five:1, but an inline gearbox can be as high as 1000:1! The torque range is between 250-950 lb-in for continuous torque, and up to 5800 lb-in for yield torque. Some companies even offer custom shafts if you need them to fit a specific application.

Inline planetary gearboxes have a high ratio of helical rotation and are useful for applications where space is limited. Their low-backlash design allows them to handle high torques and high accelerations without backlash. Despite their compact size, planetary gear systems also have high single-stage reduction ratios, a feature that makes them ideal for a variety of industrial applications. They can also be connected for high reduction ratios.

An inline planetary gearbox can be used in many applications, from small tools to heavy industrial machinery. Its basic design includes three components: an input gear pair, an output gear pair, and a stationary position. Some planetary gearbox designs also include additional gear sets that can provide a slight offset between input and output. A planetary gearbox may also contain multiple bearings, which make the assembly more robust and reliable.

Inline planetary gear reducers are commonly used in industrial settings to slow down an electric motor. They are able to multiply torque, which means they can reduce the input speed to a level where the mechanical devices inside the motor can function properly. This type of gear reducer also has a low clearance, which makes it ideal for machines with high torque. However, you should consider the amount of torque required in your application before you make a purchase.

Helical planetary gearbox

A helical planetary gearbox is a type of mechanical system. The gears are connected by joints to the carrier that holds the planets stationary. The sun gear serves as an input to the other gears, and the planet gears rotate at a rate that depends on the number of teeth in each gear. The ratio between these gears is -Ns/Np, and the number of teeth in the ring is N r, N s, and N p.

Another type of planetary gearbox uses multiple helical axes to distribute the load. This design also offers high stiffness and low backlash, which is important for applications involving frequent start-stop cycles and rotational direction changes. It also features a compact design and low mass inertia. A helical planetary gearbox can be used for a wide range of applications. Listed below are some of the benefits of helical gear technology.

The basic design of a helical planetary gear is based on the principle of stepping planets. This concept eliminates the need for timing marks and restrictive assembly conditions. The planetary gear’s helical shape can be modified to achieve a greater transmission ratio in an equal or smaller volume. For example, a 50-T ring gear will yield the same effect as a 100-T ring gear.

In addition to the helical axis, a helical planetary gearbox also has a wide variety of secondary features that are critical to torque transmission. For instance, compact needle roller bearings are appropriate for a helical planetary gearbox because of their low-profile design and small space. However, a tapered roller bearing is better suited to handling high axial forces. In general, a helical planetary gearbox will have a higher efficiency rate and lower noise levels.

A helical planetary gearbox will have a number of components that can vary in size and shape. They will include a sun gear and many planetary parts. The central sun gear will take a low-torque input and will run multiple external gears to increase the torque and speed. This basic model of a planetary gearbox is highly efficient, transferring 97% of the power input. There are three main types of planetary gearboxes: the cylindrical planetary gearbox, the helical planetary gearbox, and the helical wormwheel.

The CZPT is a good example of an entry-level helical planetary gearbox. It is extremely reliable and aimed at providing torque in quiet applications with high precision. The Access series is another option, which is designed to meet the needs of the low-backlash planetary gearbox market. It features helical planetary gears with five to eight arc-minutes backlash, and is built on a monobloc housing.

A helical planetary gearbox is widely used in 3D printing. They are lightweight and can provide a high gear ratio. In addition to their low weight and high efficiency, some people have installed them into 3D printers to improve the accuracy of their designs. And in addition to 3D printing, helical gears are used in many industrial applications. If you’re thinking about purchasing one, you should know what the benefits are.

Spur planetary gearbox

There are many advantages to a spur planetary gearbox, from its compact design and low cost to its unmatched power transmission capacity per unit volume. Planetary gears have high efficiency per stage and can achieve up to 95% efficiency, depending on the ratio. Planet gears are mounted on a joint carrier, and the output rotation speed is slower than the drive rotation speed, which leads to increased torque. The higher the gear wheels, the more torque the unit can produce.

A spur planetary gearbox incorporates multiple other gear sets that must have helical teeth. These other gear sets must be helical, and the motor must be aligned with the driven parts. The spur gears are the most efficient type of planetary gear, as their teeth are symmetrical, which means no axial forces are generated. The difference between a spur and a planetary gearbox is its shape.

The right angle spur planetary gearbox is a versatile design with a spiral bevel gear that provides superior smoothness and quiet operation. This gearhead is case-hardened and ground to increase its efficiency. These gears can be purchased in 3-100 ratios. Spur planetary gearboxes can also have ISO rotary flanges, keyed shafts, DIN splines, or hollow compression connections.

A spur planetary gearbox utilizes spur gears around the circumference of the mechanism. The spur gears rotate between gears that have internal and external teeth. Because of this, the angular velocity of the spur gear differential carrier is the average of the ring gears and sun gears. A spur gearbox can also be considered a compound planetary gear. It is typically used for servo applications. Unlike spur gears, helical planetary gears are easier to maintain and have lower noise levels.

The most notable difference between a spur planetary gearbox and a planetary gearhead is the lubrication of the pinion and the spur gear head. A spur gear head is less complex, but cannot handle the same amount of load as a planetary gearhead. Both types can achieve the same backlash, but a planetary gearhead has better lubrication retention than a spur gear. It can run at higher speeds without excessive lubrication, while a spur gear drive is more efficient at low speeds. The reduction ratio of a planetary gearhead is near unity while that of a planetary gear head is many thousand to one.

A planetary gearbox has many applications. Plastic machinery, goods & personnel lifts, and machine tools are all prime examples of these types of gearing systems. Other industries that use these gears include wind turbines and sugar crystallizers, as well as steel and sugar mills. And of course, the use of planetary gears is not limited to these industries. It is used in many different ways, including slewing drives, mill drive, and derrick & dockyard cranes

editor by czh 2023-02-15

China wholesaler gearbox ZLYJ 200 decelerator for plastic extruder with Good quality

Gearing Arrangement: Helical, Helical

Output Torque: 652~34787N.m, 652~34787N.m

Input Speed: 600~1500rpm, 600~1500rpm

Output Speed: 30~188rpm, 30~188rpm

working ambient temperature: -40~45 degree

Rotation: both forwards and backwards

Rated Power: 5.5~200kw

Warranty: 12 Months

Certification: CE; high precision NMRV030 series worm and aluminium bevel gearbox price input speed single phase 1400 rpm motor ISO, CQM, ETC

Application: extrudcer machine

Packaging Details: Standard carton/Pallet/Standard wooden case (depends on order quantity).

Port: ZheJiang

gearbox ZLYJ 200 decelerator for plastic extruder Company InformationCompany name:Guomao Reducer Group Co.,Ltd

Address: Xihu (West Lake) Dis.n District, HangZhou City, Long Life 5415 Universal Motor for Blender Hair Dryer ZheJiang Province, China.

Founding year: 1993

Quantity of employees: 2000 employees

Factory square: 360000square meters

Features of ZLYJ1. Compact size, low noise2. Steady transmission3. High efficiency

ZLYJ reducer is designed for plastic and rubber screw extruding machine with high-precision hard teeth surface.Material of the reducer is high strength alloy steel. Hardness of teeth surface is HRC54~62.

Applicable scope A: Rotating speed of high speed shaft less than 1500/minB: Circular velocity of gear drive less than 20m/sC: Working condition temp. -40~45 degree

ZLYJ Detailed Images

Packaging & Shipping

Factory Show

Certifications

Trade Partners

FAQ1. Payment Term: 30% TT in advance+70% balance before shipment or total advance.

2. Delivery time: about 20 to 30 days from receive payment.

3. We accept customized products as per your special requirement.

4.Xihu (West Lake) Dis.lines for the Selection:Usually we can select 1 machine which is suitable for you with some informations from you,such as ratio/motor speed/mounting dimension/ out torque etc.

5.If the minimum order amount is in excess of $10000, China Manufacture Low Price Advance HCA138 Marine Gearbox Transmission Set there are preferential.

Choosing a Gearbox For Your Application

The gearbox is an essential part of bicycles. It is used for several purposes, including speed and force. A gearbox is used to achieve one or both of these goals, but there is always a trade-off. Increasing speed increases wheel speed and forces on the wheels. Similarly, increasing pedal force increases the force on the wheels. This makes it easier for cyclists to accelerate their bicycles. However, this compromise makes the gearbox less efficient than an ideal one.

Dimensions

Gearboxes come in different sizes, so the size of your unit depends on the number of stages. Using a chart to determine how many stages are required will help you determine the dimensions of your unit. The ratios of individual stages are normally greater at the top and get smaller as you get closer to the last reduction. This information is important when choosing the right gearbox for your application. However, the dimensions of your gearbox do not have to be exact. Some manufacturers have guides that outline the required dimensions.

The service factor of a gearbox is a combination of the required reliability, the actual service condition, and the load that the gearbox will endure. It can range from 1.0 to 1.4. If the service factor of a gearbox is 1.0, it means that the unit has just enough capacity to meet your needs, but any extra requirements could cause the unit to fail or overheat. However, service factors of 1.4 are generally sufficient for most industrial applications, since they indicate that a gearbox can withstand 1.4 times its application requirement.

Different sizes also have different shapes. Some types are concentric, while others are parallel or at a right angle. The fourth type of gearbox is called shaft mount and is used when mounting the gearbox by foot is impossible. We will discuss the different mounting positions later. In the meantime, keep these dimensions in mind when choosing a gearbox for your application. If you have space constraints, a concentric gearbox is usually your best option.

Construction

The design and construction of a gearbox entails the integration of various components into a single structure. The components of a gearbox must have sufficient rigidity and adequate vibration damping properties. The design guidelines note the approximate values for the components and recommend the production method. Empirical formulas were used to determine the dimensions of the various components. It was found that these methods can simplify the design process. These methods are also used to calculate the angular and axial displacements of the components of the gearbox.

In this project, we used a 3D modeling software called SOLIDWORKS to create a 3-D model of a gear reducer. We used this software to simulate the structure of the gearbox, and it has powerful design automation tools. Although the gear reducer and housing are separate parts, we model them as a single body. To save time, we also removed the auxiliary elements, such as oil inlets and oil level indicators, from the 3D model.

Our method is based on parameter-optimized deep neural networks (DBNs). This model has both supervised and unsupervised learning capabilities, allowing it to be self-adaptive. This method is superior to traditional methods, which have poor self-adaptive feature extraction and shallow network generalization. Our algorithm is able to recognize faults in different states of the gearbox using its vibration signal. We have tested our model on two gearboxes.

With the help of advanced material science technologies, we can now manufacture the housing for the gearbox using high-quality steel and aluminium alloys. In addition, advanced telematics systems have increased the response time of manufacturers. These technologies are expected to create tremendous opportunities in the coming years and fuel the growth of the gearbox housing market. There are many different ways to construct a gearbox, and these techniques are highly customizable. In this study, we will consider the design and construction of various gearbox types, as well as their components.

Working

A gearbox is a mechanical device that transmits power from one gear to another. The different types of gears are called planetary gears and are used in a variety of applications. Depending on the type of gearbox, it may be concentric, parallel, or at a right angle. The fourth type of gearbox is a shaft mount. The shaft mount type is used in applications that cannot be mounted by foot. The various mounting positions will be discussed later.

Many design guidelines recommend a service factor of 1.0, which needs to be adjusted based on actual service conditions. This factor is the combined measure of external load, required reliability, and overall gearbox life. In general, published service factors are the minimum requirements for a particular application, but a higher value is necessary for severe loading. This calculation is also recommended for high-speed gearboxes. However, the service factor should not be a sole determining factor in the selection process.

The second gear of a pair of gears has more teeth than the first gear. It also turns slower, but with greater torque. The second gear always turns in the opposite direction. The animation demonstrates this change in direction. A gearbox can also have more than one pair of gears, and a first gear may be used for the reverse. When a gear is shifted from one position to another, the second gear is engaged and the first gear is engaged again.

Another term used to describe a gearbox is “gear box.” This term is an interchangeable term for different mechanical units containing gears. Gearboxes are commonly used to alter speed and torque in various applications. Hence, understanding the gearbox and its parts is essential to maintaining your car’s performance. If you want to extend the life of your vehicle, be sure to check the gearbox’s efficiency. The better its functioning, the less likely it is to fail.

Advantages

Automatic transmission boxes are almost identical to mechanical transmission boxes, but they also have an electronic component that determines the comfort of the driver. Automatic transmission boxes use special blocks to manage shifts effectively and take into account information from other systems, as well as the driver’s input. This ensures accuracy and positioning. The following are a few gearbox advantages:

A gearbox creates a small amount of drag when pedaling, but this drag is offset by the increased effort to climb. The external derailleur system is more efficient when adjusted for friction, but it does not create as little drag in dry conditions. The internal gearbox allows engineers to tune the shifting system to minimize braking issues, pedal kickback, and chain growth. As a result, an internal gearbox is a great choice for bikes with high-performance components.

Helical gearboxes offer some advantages, including a low noise level and lower vibration. They are also highly durable and reliable. They can be extended in modular fashion, which makes them more expensive. Gearboxes are best for applications involving heavy loads. Alternatively, you can opt for a gearbox with multiple teeth. A helical gearbox is more durable and robust, but it is also more expensive. However, the benefits far outweigh the disadvantages.

A gearbox with a manual transmission is often more energy-efficient than one with an automatic transmission. Moreover, these cars typically have lower fuel consumption and higher emissions than their automatic counterparts. In addition, the driver does not have to worry about the brakes wearing out quickly. Another advantage of a manual transmission is its affordability. A manual transmission is often available at a lower cost than its automatic counterpart, and repairs and interventions are easier and less costly. And if you have a mechanical problem with the gearbox, you can control the fuel consumption of your vehicle with appropriate driving habits.

Application

While choosing a gearbox for a specific application, the customer should consider the load on the output shaft. High impact loads will wear out gear teeth and shaft bearings, requiring higher service factors. Other factors to consider are the size and style of the output shaft and the environment. Detailed information on these factors will help the customer choose the best gearbox. Several sizing programs are available to determine the most appropriate gearbox for a specific application.

The sizing of a gearbox depends on its input speed, torque, and the motor shaft diameter. The input speed must not exceed the required gearbox’s rating, as high speeds can cause premature seal wear. A low-backlash gearbox may be sufficient for a particular application. Using an output mechanism of the correct size may help increase the input speed. However, this is not recommended for all applications. To choose the right gearbox, check the manufacturer’s warranty and contact customer service representatives.

Different gearboxes have different strengths and weaknesses. A standard gearbox should be durable and flexible, but it must also be able to transfer torque efficiently. There are various types of gears, including open gearing, helical gears, and spur gears. Some of the types of gears can be used to power large industrial machines. For example, the most popular type of gearbox is the planetary drive gearbox. These are used in material handling equipment, conveyor systems, power plants, plastics, and mining. Gearboxes can be used for high-speed applications, such as conveyors, crushers, and moving monorail systems.

Service factors determine the life of a gearbox. Often, manufacturers recommend a service factor of 1.0. However, the actual value may be higher or lower than that. It is often useful to consider the service factor when choosing a gearbox for a particular application. A service factor of 1.4 means that the gearbox can handle 1.4 times the load required. For example, a 1,000-inch-pound gearbox would need a 1,400-inch-pound gearbox. Service factors can be adjusted to suit different applications and conditions.

in Bellary India sales price shop near me near me shop factory supplier Single-Screw Plastic Extruder Gearbox manufacturer best Cost Custom Cheap wholesaler

The new merchandise consist of a series of high-tech and high high quality chains and sprockets and gears, this kind of as chains and gearboxes for agricultural machineries, metallurgical chains, escalator phase-chains, substantial-pace tooth chains, timing chains, self-lubrication chains, amid which have sort higher speed tooth chain for vehicle branch dynamic box and aerial chains fill in the blanks of chain in China. our items are marketing properly in the American, European, South American and Asian markets. Obtaining gathered valuable knowledge in cooperating with international clients, ZLYJ EPTT collection are EPTT gadgets comma which are EPTTly designed for one-screw extruEPTTwith higher precision comma tough EPT surface area comma accompany with thrust period of time Adopting the technical specs stipulated in JB solT9050 period1-1999 comma all ZLYJ EPTTes are designed accordingly interval

Major Functions of velocity EPT box colon

1 interval The substance of EPT is the substantial toughness alloy metal comma it is produced by carburizing comma quenching lparand other warmth remedy rpar comma grinding approach at very last interval The EPT is in higher precision lpar6grade rpar and substantial hardness lparreaches EPTC54-62 rpar period Besides comma it functions lower sound when running period

two interval It includes substantial bearing ability thrust comma which is executed dependable and can withstand bigger aXiHu (West EPT) Dis.al thrust period of time interval period of time

3 period All the things are taken care of by pressured lubrication and cooling method other than very couple of little specification products interval

4 time period ZLYJ sequence EPTT is adpoted by six-aspect processing box period of time Its normal set up is horizontal comma but can also transformed to vertical set up according to client aposs erquirement interval

five interval Effectiveness EPTT comma reduced sounds comma EPTT operation time period

| Sort | Spec. | Output

EPTT(KW) |

Enter (n) | Output (n) | Output

torque (N@ m) |

AXiHu (West EPT) Dis.al

Thrust(KN) |

Screw

Diameter |

Length

Diamerer Ratio |

| ZSYJ | 630-44 | 315 | 1500 | 34 | 88471 | 770 | two hundred | 25:1 |

Best China manufacturer & factory china in Chongjin Dem. People’s Republic of Korea supplier ZLYJ series gearbox rubber screw Extruder Gear box reducer for plastic extrusion machine With high quality best price

With a lot of years’ expertise in these strains, we have been distinguished from other suppliers in China by our rewards in aggressive pricing, on-time delivery, prompt responses, on-hand engineering assist and good after-product sales providers.

Overview

Rapid Specifics

- Applicable Industries:

-

Production Plant

- Pole:

-

one phase two stage a few phase 4 stage

- Ratio:

-

one.twenty five-ninety

-

EPG Team PTO shafts can be used for speeds up to one thousand rpm. The greatest functioning size of the PTO shafts may differ in accordance to the size of the tubes The range of the PTO shafts of RPG Group contains 4 collection , in accordance to the tube form

- Housing Material:

-

Cast Iron

- Substance:

-

20CrMoTi

- Operating temperature:

-

-40~45℃

- Sort:

-

ZLYJ collection gearbox rubber screw Extruder Equipment box reducer for plastic

- Approach:

-

Carburizing, Nitriding , Grinding

- Effectiveness:

-

ninety two%~96%

- Mounting Position:

-

Horizontal,Vertical,Flange

- Shade:

-

Blue,Inexperienced,Gray,Crimson

Packaging & Delivery

-

Direct Time

: -

Quantity(Luggage) 1 – 20 >20 Est. Time(days) eighteen To be negotiated

Online Customization

Solution Description

Professional MANUFACTURE

—— Since 1995

ZLYJ Extruder GearBox

Ever-Power Equipment —— Tianqi Brand industrial gearbox manufacturers

ZLYJ 173/one hundred eighty/two hundred/375 cleaning soap Extruder Gearboxes for plastic extrusion equipment

Major Series Product: R collection helical gear reducer, K series spiral bevel equipment reducer, NGW, P series planetary reducer, H B collection gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical equipment reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloid reducer,ZLYJ Series twin screw extruder gearbox for extruder device, and so forth. In the meantime, map sample processing organization can be undertaken.

Commonly utilised in mining equipment, chemical sector,metal metallurgy, light industry,environmental security, paper creating, printing, lifting transportation, food industry and so on.

Specification

ZLYJ ZLYJ 173/one hundred eighty/two hundred/375 soap Extruder Gearboxes for plastic extrusion equipment twin screw extruder Gearbox:

Feature:

-

Understood parallel shaft,appropriate-angle shaft modes and horizontal,vertical mounting modes. Using significantly less ingredient areas.

-

Implementing sophisticated grinding method which enhanced the balance and the efficiency of transmit power with In order to find a ideal gearbox for your software from the standard segment, our online SIZING ASSISTANT design and style tool is excellent: dependent on your software information or the wanted motor, a suitable gearbox can be chosen from our portfolio and geometry adjustment executed in a handful of seconds. Upon desire, we can also send you a request for quotation right on the web.reduce noise.H B Bevel helical reduction gearbox fifty:1 for bucket elevators.

-

Input manner: motor linked flange, shaft input.

-

Output method:reliable shaft with flat essential,hollow shaft with flat important,hollow shaft with shrink disk,hollow shaft with spline link, solid shaft with spline relationship, solid shaft with flange.

-

Mounting manner:vertical, horizontal, swing foundation-mounted, torque-arm-mounted.

-

Ratio variety:8~20.

| Variety | ZLYJ133 | ZLYJ146 | ZLYJ173 | ZLYJ200 | ZLYJ225 | ZLYJ280 | ZLYJ315 | ZLYJ330 | ZLYJ420 |

| n | eight | eight | eight | twelve | twelve | 12 | twelve | 12 | 12 |

| d3 | M12 | M12 | M16 | M16 | M20 | M20 | M24 | M24 | M24 |

| centre distance | 205 | 230 | 260 | three hundred | 370 | 400 | 405 | 450 | 580 |

Model choice:

Intently using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is extremely crucial for the life of reducer, and spend interest to whether the greatest torque benefit (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is generally the applicable electricity of the servo versions on the market, the applicability of the reducer is really high, the operating coefficient can be managed earlier mentioned 1.2, but the decision can also be primarily based on their personal wants to choose.Industrial Gearbox Companies H B Collection Substantial rpm Gearbox Reduction with 6: 1 ratio.H B Bevel helical reduction gearbox fifty:1 for bucket elevators.fertilizer spreader gearbox reduction fifty:1 rates. ZLYJ 173/a hundred and eighty/200/375 soap Extruder Gearboxes for plastic extrusion machine.

Technologies

Firm Info

Established in 1995 , HangZhou Ever-Power Machinery is a skilled manufacturer and exporter that is concerned with the style, growth and generation of Gearbox Pace Reducer. We are found in HangZhou of ZheJiang Province, with handy transportation accessibility. With our possess brand “EPG”, all of our products comply with international high quality expectations and are drastically appreciated in a range of various marketplaces all through the globe.

Our company possesses complete machining center, lathe, equipment shaping device, gear milling device, gear grinding equipment and assembling traces. Our nicely-outfitted amenities and outstanding good quality handle all through all levels of creation allows us to assure total consumer satisfaction.

Aside from, In 2005,we attained ISO9001 certification. As a end result of our substantial top quality merchandise and excellent client provider, we have acquired a global income network reaching South America, Saudi Arabia, Vietnam, Pakistan, Philippines, South Africa and other countries and locations.

With abundant export encounter, substantial quality products, competitive rates, good services and in-time supply, we certain that we can meet up with all of your necessity and exceed your expectations. Our feature is bright with new cooperative relationships with companies from all over the globe. We seem forward to speaking with you to future discuss how we can be of support to you.

Chinese Equipment Velocity ReduceUnder the assistance of managerial sense of “Serving agriculture, scoring a good results through quality of products and honesty in business”, our items have been trustworthy by consumers and have gained a greater share of marketplace.r is a mechanical transmission in a lot of fields of the nationwide economy. The merchandise classes protected by the market include all sorts of equipment reducer, planetary equipment reducer and worm gearbox, as nicely as numerous specific transmission products this kind of as velocity growing gadget, velocity control Gadgets, like various kinds of versatile transmission products, this sort of as compound transmission. Goods and solutions in the area of metallurgy, nonferrous metals, coal, building components, ships, drinking water conservancy, electrical power, construction machinery and petrochemical industries.

In all fields of countrywide economic system and nationwide defense industry, gearbox products have a wide selection of programs. Food light-weight business, electrical equipment, building equipment, metallurgy equipment, cement equipment, environmental defense equipment, electronic appliances, road design equipment, h2o conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building supplies machinery, rubber machinery, petroleum machinery and other industries have sturdy need of Reducer products.Industrial Gearbox Makers H B Sequence Large rpm Gearbox Reduction with 6: 1 ratio.H B Bevel helical reduction gearbox 50:1 for bucket elevators.1:forty ratio.3: 1 ratio gearbox.1:30 ratio gearbox.fertilizer spreader gearbox reduction 50:1 rates. ZLYJ 173/a hundred and eighty/two hundred/375 cleaning soap Extruder Gearboxes for plastic extrusion device.

Packaging & Shipping and delivery

FAQ

1.Q:Are you the manufacturing unit or buying and selling firm?

A:We are the Factory, with 23 several years of manufacturing knowledge.

2.Q:Can you customise according to our requirements?

A:Of course, we can design and style nonstandard merchandise in accordance to customer’s drawing and sample.

three.Q:How lengthy is the shipping and delivery date?

A:ten-20 functioning days. Cutomized variety require to according to the quantity.

4.Q:The place is your manufacturing unit?

A:We are in HangZhou of ZheJiang Province, you can get below by higher speed prepare or fly to Jinan.

Welcome to pay a visit to us!

5.Q:What’s your payment terms?

A:TT 30% as deposite, 70% banlance compensated prior to shipping.