Product Description

Overview

Product Description

Wide Selection of Gearbox Products

The gearbox usually adopts a general design scheme, but in special cases, the design scheme of the gearbox can be changed according to the demands of the user, and it can be modified into an industry-specific gearbox. In the design scheme of the gearbox, the parallel shaft, vertical shaft, general box, and various parts can be changed

Advantages

- Absorption of very high torques and axial forces

- No need for separate thrust housing & bearing.

- Easy alignment (screw directly fits into the vore of gear box)

- Easy to assemble & dismantle.

- Very heavy duty spherical roller thrust bearing is provided.

- Power saving. (you may save up to 20 % power.)

- Less requirement of space.

- For bigger sizes water cooling is provided

- No maintenance required except periodic oil level checking.

- Higher productivity

Features

- Twin Screw Extruder Gearboxes offer the dual shaft counter rotating. The range is available for various center distances

- The gearboxes are available with co-rotating and counter rotating variants

- To work under heavy loading force, the high level dissipation and oil lubrication system are provided. The axial roller type swivel thrust with the thrust bearing coupled in tandem way support the axial thrust

- High torque and high speed output rate

Processing Characteristics of Screw Shaft:

1.Suitable suggestion on material to ensure components performance and extend lifetime of products.

2.Professional technical team can provide surveying and mapping support.

3.All components are finished by CNC machine.

4.Sophisticated quality management system ensure superior quality.

Basic Info.

| Warranty: 1 year | Weight (KG): 500 KG |

| Place of Origin: HangZhou, China |

Gearing Arrangement: helical |

| ratio: 8-20 |

Output Torque: 2*176 |

| standard: JB/T8853-2001 |

Certificate: CE |

| Heat treatment: High-frequency Hardening |

Efficiency: 94%~98%(depends on the transmission stage) |

| Customized support:OEM ODM | Input/output shaft material 40Cr |

| Package: Wooden case |

Mount position: Flange, hollow shaft, CZPT shaft |

| After-sale:Online 24/7 Installation Xihu (West Lake) Dis. | advantage: excellent quality |

| Reduction radio: 3:1 |

Mount Position: Horizontal Foot Mounted Vertical |

| Input Speed: 1500 |

Output Speed: 500 |

Packaging & delivery

|

Packing: wooden case packing |

|

| Port: HangZhou Port |

Applications

X helical gear units for double-screw extruders with parallel drive shafts and the same direction of screw rotation are used mainly in the manufacture of granulates and the refining of raw plastics. Other areas of application include:

- Paint and lacquer industry

- Washing agent industry

- Foodstuff industry (e.g. bread, pasta)

- Animal-feed industry (dog, cat other animal food

Maintenance of the gearbox of the dual-screw extruder

1. The gear box of the dual-screw extruder should be well-ventilated, and the working environment temperature should be within the range of 5-35 °C.

2. Always check the oil quantity of the gear lubricating oil in the box to ensure that the transmission parts in the box are well lubricated.

3. Pay attention to check the bearing parts of the box frequently. The oil temperature of the oil tank of the transmission box should not exceed 70 ºC during operation.

4. The newly put into use gearbox needs to replace the lubricating oil after 250 hours of operation. The oil change time depends on the state of the oil. It is recommended to replace it after 4000-8000 hours of operation or once a year.

5. The gearbox of the dual-screw extruder needs to be regularly maintained and inspected once a year

Operating Process

1. The gear on the input shaft is driven by the motor and starts to rotate.

2. The rotating input gear meshes with other gears inside the gearbox, transmitting power.

3. Different-sized gears within the gearbox are combined to form a gear train. Through continuous meshing and rotation, the high-speed, low-torque power from the input shaft gradually converts into low-speed, high-torque output.

4. The output shaft is connected to the last gear and transfers the output torque to the load.

5. Gear reduction gearboxes typically include lubrication and cooling systems to ensure smooth operation and prevent overheating and damage.

6. Our extruder gearbox converts high-speed, low-torque power into low-speed, high-torque output by changing the size ratios and meshing arrangements of different gears, achieving the function of speed reduction.

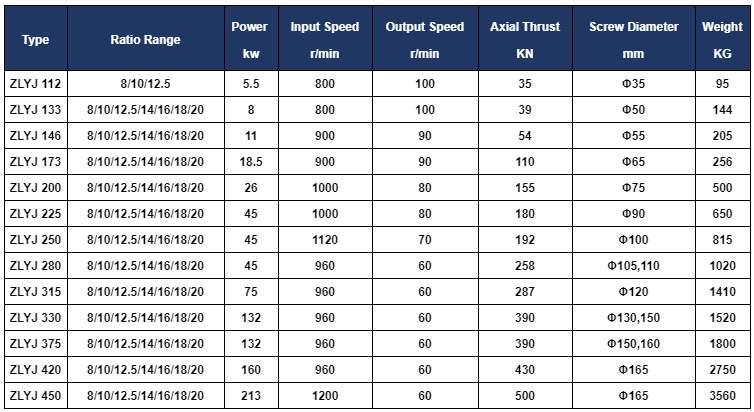

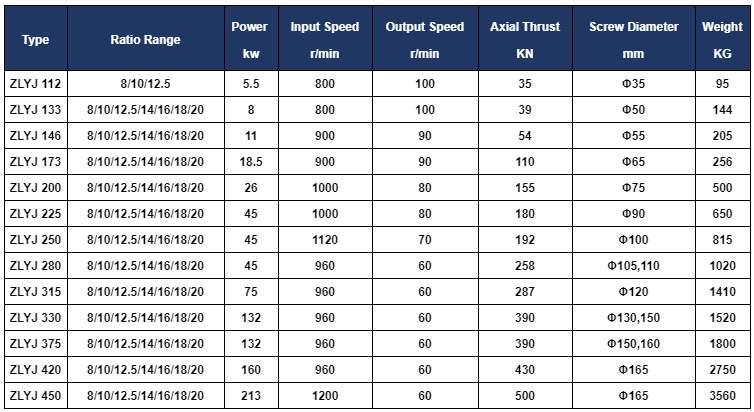

Types of Gearboxes:

Based on customer requirements, gear reduction gearboxes can be classified according to the size of the output shaft, center distance of the output shaft, output speed, and torque. Alternatively, we can provide several commonly used types of gearboxes for customers to choose from.

Product Service

|

24-hour Hotline

No matter when and where to call we can find our service to you.

|

Pre-sales Consultation

We have 5 sales people online, and whether you have any question can be solved through online communication. |

After-sales Services

Receive products have any questions about the product, can look for us,we will help you deal with the the first time,to your satisfaction. |

Exhibition

Certificate

Company profile

ZheJiang Arrow Machinery Co., Ltd.is a company specializing in R&D, production, sales, application promotion of food engineering projects. As 1 of the largest scaled food processing equipment &whole plant engineering problem solvers in China, machines served for more than 970 companies, export to 116 countries, area, more than 20 years engineering team, we recognize that quality equals value, aims to create a great future together with global customers.

FAQ

1. Q: How about Arrow Machinery?

R: ZheJiang Arrow Machinery Co., Ltd. is a High-Tech company. Our firm is composed of a strong

team which has substantial experience in R&D, manufacture, technique and sales service and has

specialized in extruder industry for 10 years,leading screw barrel manufacturer in China.

2. Q:What’s Arrow machinery’s capacity?

R:Company is in strict accordance with CE and ISO9001 quality certification system.There are over 200

models of extruders and spare parts.

3. Q:What’s the delivery time?

R:For regular size, we have finished stock and semi-finished stock, 2 weeks max enough

for customized, normally within 20days .

4. Q:How about the gearbox quality and price?

R: top quality in China with competitive price and globle after-sale service

5. Q:what’s the life time and guarantee buy from Arrow machinery ?

R: 3~5years life time for nitriding ones and bimtallic ones will be longer

One year min. Guarantee.

6.Q:Where is Arrow Machinery factory and how to reach there?

R:NO.47 Chengbohu Road, Xihu (West Lake) Dis. District,HangZhou City, China. You can take the train or plane to HangZhou and we can pick you up.

7.Q:How to contact with you?

R:just reply to me if have any question.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Cycloidal |

| Samples: |

US$ 99999/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Challenges in Achieving High Gear Ratios with Compactness in Planetary Gearboxes

Designing planetary gearboxes with high gear ratios while maintaining a compact form factor poses several challenges due to the intricate arrangement of gears and the need to balance various factors:

Space Constraints: Increasing the gear ratio typically requires adding more planetary stages, resulting in additional gears and components. However, limited available space can make it challenging to fit these additional components without compromising the compactness of the gearbox.

Efficiency: As the number of planetary stages increases to achieve higher gear ratios, there can be a trade-off in terms of efficiency. Additional gear meshings and friction losses can lead to decreased overall efficiency, impacting the gearbox’s performance.

Load Distribution: The distribution of loads across multiple stages becomes critical when designing high gear ratio planetary gearboxes. Proper load distribution ensures that each stage shares the load proportionally, preventing premature wear and ensuring reliable operation.

Bearing Arrangement: Accommodating multiple stages of planetary gears requires an effective bearing arrangement to support the rotating components. Improper bearing selection or arrangement can lead to increased friction, reduced efficiency, and potential failures.

Manufacturing Tolerances: Achieving high gear ratios demands tight manufacturing tolerances to ensure accurate gear tooth profiles and precise gear meshing. Any deviations can result in noise, vibration, and reduced performance.

Lubrication: Adequate lubrication becomes crucial in maintaining smooth operation and reducing friction as gear ratios increase. However, proper lubrication distribution across multiple stages can be challenging, impacting efficiency and longevity.

Noise and Vibration: The complexity of high gear ratio planetary gearboxes can lead to increased noise and vibration levels due to the higher number of gear meshing interactions. Managing noise and vibration becomes essential for ensuring acceptable performance and user comfort.

To address these challenges, engineers employ advanced design techniques, high-precision manufacturing processes, specialized materials, innovative bearing arrangements, and optimized lubrication strategies. Achieving the right balance between high gear ratios and compactness involves careful consideration of these factors to ensure the gearbox’s reliability, efficiency, and performance.

Enhancing Wind Turbine System Performance with Planetary Gearboxes

Planetary gearboxes play a crucial role in enhancing the performance and efficiency of wind turbine systems. Here’s how they contribute:

1. Speed Conversion: Wind turbines operate optimally at specific rotational speeds to generate electricity efficiently. Planetary gearboxes allow for speed conversion between the low rotational speed of the wind turbine rotor and the higher speed required by the generator. This speed adaptation ensures the generator operates at its peak efficiency, resulting in maximum power generation.

2. Torque Amplification: Wind turbine blades may experience varying wind speeds, which result in fluctuating torque loads. Planetary gearboxes can amplify the torque generated by the rotor blades before transmitting it to the generator. This torque multiplication helps maintain stable generator operation even during wind speed variations, improving overall energy production.

3. Compact Design: Wind turbines are often installed in locations with limited space, such as offshore platforms or densely populated areas. Planetary gearboxes offer a compact design, allowing for efficient power transmission within a small footprint. This compactness is vital for accommodating gearboxes in the limited nacelle space of the wind turbine.

4. Load Distribution: Wind turbines are subjected to varying wind conditions, including gusts and turbulence. Planetary gearboxes distribute the load evenly among multiple planet gears, reducing stress and wear on individual components. This balanced load distribution improves gearbox durability and reliability.

5. Efficiency Optimization: Planetary gearboxes are known for their high efficiency due to their parallel axis arrangement and multiple gear stages. The efficient power transmission minimizes energy losses within the gearbox, resulting in more power being converted from wind energy to electricity.

6. Maintenance and Reliability: The robust construction of planetary gearboxes contributes to their durability and longevity. Wind turbines often operate in challenging environments, and the reliability of the gearbox is crucial for minimizing maintenance and downtime. Planetary gearboxes’ low maintenance requirements and ability to handle varying loads contribute to the overall reliability of wind turbine systems.

7. Variable Speed Control: Some wind turbines use variable-speed operation to optimize power generation across a range of wind speeds. Planetary gearboxes can facilitate variable speed control by adjusting the gear ratio to match the wind conditions. This flexibility improves energy capture and reduces stress on turbine components.

8. Adaptation to Turbine Size: Planetary gearboxes are available in various sizes and gear ratios, making them adaptable to different turbine sizes and power outputs. This versatility allows wind turbine manufacturers to select gearboxes that align with specific project requirements.

Overall, planetary gearboxes play a pivotal role in optimizing the performance, efficiency, and reliability of wind turbine systems. Their ability to convert speed, amplify torque, and distribute loads makes them a key component in harnessing wind energy for clean and sustainable electricity generation.

Challenges and Solutions for Managing Power Transmission Efficiency in Planetary Gearboxes

Managing power transmission efficiency in planetary gearboxes is crucial to ensure optimal performance and minimize energy losses. Several challenges and solutions are involved in maintaining high efficiency:

1. Gear Meshing Efficiency: The interaction between gears can lead to energy losses due to friction and meshing misalignment. To address this, manufacturers use precision manufacturing techniques to ensure accurate gear meshing and reduce friction. High-quality materials and surface treatments are also employed to minimize wear and friction.

2. Lubrication: Proper lubrication is essential to reduce friction and wear between gear surfaces. Using high-quality lubricants with the appropriate viscosity and additives can enhance power transmission efficiency. Regular maintenance and monitoring of lubrication levels are vital to prevent efficiency losses.

3. Bearing Efficiency: Bearings support the rotating elements of the gearbox and can contribute to energy losses if not properly designed or maintained. Choosing high-quality bearings and ensuring proper alignment and lubrication can mitigate efficiency losses in this area.

4. Bearing Preload: Incorrect bearing preload can lead to increased friction and efficiency losses. Precision assembly and proper adjustment of bearing preload are necessary to optimize power transmission efficiency.

5. Mechanical Losses: Various mechanical losses, such as windage and churning losses, can occur in planetary gearboxes. Designing gearboxes with streamlined shapes and efficient ventilation systems can reduce these losses and enhance overall efficiency.

6. Material Selection: Choosing appropriate materials with high strength and minimal wear characteristics is essential for reducing power losses due to material deformation and wear. Advanced materials and surface coatings can be employed to enhance efficiency.

7. Noise and Vibration: Excessive noise and vibration can indicate energy losses in the form of mechanical inefficiencies. Proper design and precise manufacturing techniques can help minimize noise and vibration, indicating better power transmission efficiency.

8. Efficiency Monitoring: Regular efficiency monitoring through testing and analysis allows engineers to identify potential issues and optimize gearbox performance. This proactive approach ensures that any efficiency losses are promptly addressed.

By addressing these challenges through careful design, material selection, manufacturing techniques, lubrication, and maintenance, engineers can manage power transmission efficiency in planetary gearboxes and achieve high-performance power transmission systems.

editor by CX 2024-04-12

China Professional CZPT Arrow Znfpy-78 High Torque Rpm Reverse Gearbox for Plastic Twin Screw Extruder car gearbox

Product Description

Overview

Product Description

Wide Selection of Gearbox Products

The gearbox usually adopts a general design scheme, but in special cases, the design scheme of the gearbox can be changed according to the demands of the user, and it can be modified into an industry-specific gearbox. In the design scheme of the gearbox, the parallel shaft, vertical shaft, general box, and various parts can be changed

Advantages

- Absorption of very high torques and axial forces

- No need for separate thrust housing & bearing.

- Easy alignment (screw directly fits into the vore of gear box)

- Easy to assemble & dismantle.

- Very heavy duty spherical roller thrust bearing is provided.

- Power saving. (you may save up to 20 % power.)

- Less requirement of space.

- For bigger sizes water cooling is provided

- No maintenance required except periodic oil level checking.

- Higher productivity

Features

- Twin Screw Extruder Gearboxes offer the dual shaft counter rotating. The range is available for various center distances

- The gearboxes are available with co-rotating and counter rotating variants

- To work under heavy loading force, the high level dissipation and oil lubrication system are provided. The axial roller type swivel thrust with the thrust bearing coupled in tandem way support the axial thrust

- High torque and high speed output rate

Processing Characteristics of Screw Shaft:

1.Suitable suggestion on material to ensure components performance and extend lifetime of products.

2.Professional technical team can provide surveying and mapping support.

3.All components are finished by CNC machine.

4.Sophisticated quality management system ensure superior quality.

Basic Info.

| Warranty: 1 year | Weight (KG): 500 KG |

| Place of Origin: HangZhou, China |

Gearing Arrangement: helical |

| ratio: 8-20 |

Output Torque: 2*176 |

| standard: JB/T8853-2001 |

Certificate: CE |

| Heat treatment: High-frequency Hardening |

Efficiency: 94%~98%(depends on the transmission stage) |

| Customized support:OEM ODM | Input/output shaft material 40Cr |

| Package: Wooden case |

Mount position: Flange, hollow shaft, CZPT shaft |

| After-sale:Online 24/7 Installation Xihu (West Lake) Dis. | advantage: excellent quality |

| Reduction radio: 3:1 |

Mount Position: Horizontal Foot Mounted Vertical |

| Input Speed: 1500 |

Output Speed: 500 |

Packaging & delivery

|

Packing: wooden case packing |

|

| Port: HangZhou Port |

Applications

X helical gear units for double-screw extruders with parallel drive shafts and the same direction of screw rotation are used mainly in the manufacture of granulates and the refining of raw plastics. Other areas of application include:

- Paint and lacquer industry

- Washing agent industry

- Foodstuff industry (e.g. bread, pasta)

- Animal-feed industry (dog, cat other animal food

Maintenance of the gearbox of the dual-screw extruder

1. The gear box of the dual-screw extruder should be well-ventilated, and the working environment temperature should be within the range of 5-35 °C.

2. Always check the oil quantity of the gear lubricating oil in the box to ensure that the transmission parts in the box are well lubricated.

3. Pay attention to check the bearing parts of the box frequently. The oil temperature of the oil tank of the transmission box should not exceed 70 ºC during operation.

4. The newly put into use gearbox needs to replace the lubricating oil after 250 hours of operation. The oil change time depends on the state of the oil. It is recommended to replace it after 4000-8000 hours of operation or once a year.

5. The gearbox of the dual-screw extruder needs to be regularly maintained and inspected once a year

Operating Process

1. The gear on the input shaft is driven by the motor and starts to rotate.

2. The rotating input gear meshes with other gears inside the gearbox, transmitting power.

3. Different-sized gears within the gearbox are combined to form a gear train. Through continuous meshing and rotation, the high-speed, low-torque power from the input shaft gradually converts into low-speed, high-torque output.

4. The output shaft is connected to the last gear and transfers the output torque to the load.

5. Gear reduction gearboxes typically include lubrication and cooling systems to ensure smooth operation and prevent overheating and damage.

6. Our extruder gearbox converts high-speed, low-torque power into low-speed, high-torque output by changing the size ratios and meshing arrangements of different gears, achieving the function of speed reduction.

Types of Gearboxes:

Based on customer requirements, gear reduction gearboxes can be classified according to the size of the output shaft, center distance of the output shaft, output speed, and torque. Alternatively, we can provide several commonly used types of gearboxes for customers to choose from.

Product Service

|

24-hour Hotline

No matter when and where to call we can find our service to you.

|

Pre-sales Consultation

We have 5 sales people online, and whether you have any question can be solved through online communication. |

After-sales Services

Receive products have any questions about the product, can look for us,we will help you deal with the the first time,to your satisfaction. |

Exhibition

Certificate

Company profile

ZheJiang Arrow Machinery Co., Ltd.is a company specializing in R&D, production, sales, application promotion of food engineering projects. As 1 of the largest scaled food processing equipment &whole plant engineering problem solvers in China, machines served for more than 970 companies, export to 116 countries, area, more than 20 years engineering team, we recognize that quality equals value, aims to create a great future together with global customers.

FAQ

1. Q: How about Arrow Machinery?

R: ZheJiang Arrow Machinery Co., Ltd. is a High-Tech company. Our firm is composed of a strong

team which has substantial experience in R&D, manufacture, technique and sales service and has

specialized in extruder industry for 10 years,leading screw barrel manufacturer in China.

2. Q:What’s Arrow machinery’s capacity?

R:Company is in strict accordance with CE and ISO9001 quality certification system.There are over 200

models of extruders and spare parts.

3. Q:What’s the delivery time?

R:For regular size, we have finished stock and semi-finished stock, 2 weeks max enough

for customized, normally within 20days .

4. Q:How about the gearbox quality and price?

R: top quality in China with competitive price and globle after-sale service

5. Q:what’s the life time and guarantee buy from Arrow machinery ?

R: 3~5years life time for nitriding ones and bimtallic ones will be longer

One year min. Guarantee.

6.Q:Where is Arrow Machinery factory and how to reach there?

R:NO.47 Chengbohu Road, Xihu (West Lake) Dis. District,HangZhou City, China. You can take the train or plane to HangZhou and we can pick you up.

7.Q:How to contact with you?

R:just reply to me if have any question.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Cycloidal |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Challenges in Achieving High Gear Ratios with Compactness in Planetary Gearboxes

Designing planetary gearboxes with high gear ratios while maintaining a compact form factor poses several challenges due to the intricate arrangement of gears and the need to balance various factors:

Space Constraints: Increasing the gear ratio typically requires adding more planetary stages, resulting in additional gears and components. However, limited available space can make it challenging to fit these additional components without compromising the compactness of the gearbox.

Efficiency: As the number of planetary stages increases to achieve higher gear ratios, there can be a trade-off in terms of efficiency. Additional gear meshings and friction losses can lead to decreased overall efficiency, impacting the gearbox’s performance.

Load Distribution: The distribution of loads across multiple stages becomes critical when designing high gear ratio planetary gearboxes. Proper load distribution ensures that each stage shares the load proportionally, preventing premature wear and ensuring reliable operation.

Bearing Arrangement: Accommodating multiple stages of planetary gears requires an effective bearing arrangement to support the rotating components. Improper bearing selection or arrangement can lead to increased friction, reduced efficiency, and potential failures.

Manufacturing Tolerances: Achieving high gear ratios demands tight manufacturing tolerances to ensure accurate gear tooth profiles and precise gear meshing. Any deviations can result in noise, vibration, and reduced performance.

Lubrication: Adequate lubrication becomes crucial in maintaining smooth operation and reducing friction as gear ratios increase. However, proper lubrication distribution across multiple stages can be challenging, impacting efficiency and longevity.

Noise and Vibration: The complexity of high gear ratio planetary gearboxes can lead to increased noise and vibration levels due to the higher number of gear meshing interactions. Managing noise and vibration becomes essential for ensuring acceptable performance and user comfort.

To address these challenges, engineers employ advanced design techniques, high-precision manufacturing processes, specialized materials, innovative bearing arrangements, and optimized lubrication strategies. Achieving the right balance between high gear ratios and compactness involves careful consideration of these factors to ensure the gearbox’s reliability, efficiency, and performance.

Impact of Temperature Variations and Environmental Conditions on Planetary Gearbox Performance

The performance of planetary gearboxes can be significantly influenced by temperature variations and environmental conditions. Here’s how these factors impact their operation:

Temperature Variations: Extreme temperature fluctuations can affect the lubrication properties of the gearbox. Cold temperatures can cause the lubricant to thicken, leading to increased friction and reduced efficiency. On the other hand, high temperatures can cause the lubricant to thin out, potentially leading to insufficient lubrication and accelerated wear.

Environmental Contaminants: Planetary gearboxes used in outdoor or industrial environments can be exposed to contaminants such as dust, dirt, moisture, and chemicals. These contaminants can infiltrate the gearbox and degrade the quality of the lubricant. Additionally, abrasive particles can cause wear on gear surfaces, leading to decreased performance and potential damage.

Corrosion: Exposure to moisture, especially in humid or corrosive environments, can lead to corrosion of gearbox components. Corrosion weakens the structural integrity of gears and other components, which can ultimately result in premature failure.

Thermal Expansion: Temperature changes can cause materials to expand and contract. In gearboxes, this can lead to misalignment of gears and improper meshing, causing noise, vibration, and reduced efficiency. Proper consideration of thermal expansion is crucial in gearbox design.

Sealing and Ventilation: To mitigate the impact of temperature and environmental factors, planetary gearboxes need effective sealing to prevent contaminants from entering and to retain the lubricant. Proper ventilation is also essential to prevent pressure build-up inside the gearbox due to temperature changes.

Cooling Systems: In applications where temperature control is critical, cooling systems such as fans or heat exchangers can be incorporated to maintain optimal operating temperatures. This helps prevent overheating and ensures consistent gearbox performance.

Overall, temperature variations and environmental conditions can have a profound impact on the performance and lifespan of planetary gearboxes. Manufacturers and operators need to consider these factors during design, installation, and maintenance to ensure reliable and efficient operation.

Role of Sun, Planet, and Ring Gears in Planetary Gearboxes

The arrangement of sun, planet, and ring gears is a fundamental aspect of planetary gearboxes and significantly contributes to their performance. Each gear type plays a specific role in the gearbox’s operation:

- Sun Gear: The sun gear is located at the center and is driven by the input power source. It transmits torque to the planet gears, causing them to orbit around it. The sun gear’s size and rotation speed affect the overall gear ratio of the system.

- Planet Gears: Planet gears are smaller gears that surround the sun gear. They are held in place by the planet carrier and mesh with both the sun gear and the internal teeth of the ring gear. As the sun gear rotates, the planet gears revolve around it, engaging with both the sun and ring gears simultaneously. This arrangement multiplies torque and changes the direction of rotation.

- Ring Gear (Annulus Gear): The ring gear is the outermost gear with internal teeth that mesh with the planet gears’ external teeth. It remains stationary or acts as the output shaft. The interaction between the planet gears and the ring gear causes the planet gears to rotate on their own axes as they orbit the sun gear.

The arrangement of these gears allows for various gear reduction ratios and torque multiplication effects, making planetary gearboxes versatile and efficient for a wide range of applications. The combination of multiple gear engagements and interactions distributes the load across multiple gear teeth, resulting in higher torque capacity, smoother operation, and lower stress on individual gear teeth.

Planetary gearboxes offer advantages such as compact size, high torque density, and the ability to achieve multiple gear reduction stages within a single unit. The arrangement of the sun, planet, and ring gears is essential for achieving these benefits while maintaining efficiency and reliability in various mechanical systems.

editor by CX 2024-04-09

China best CZPT Arrow Various Type of Gearbox for Twin Screw Extruder gearbox definition

Product Description

Overview

Product Description

Wide Selection of Gearbox Products

The gearbox usually adopts a general design scheme, but in special cases, the design scheme of the gearbox can be changed according to the demands of the user, and it can be modified into an industry-specific gearbox. In the design scheme of the gearbox, the parallel shaft, vertical shaft, general box, and various parts can be changed

Advantages

- Absorption of very high torques and axial forces

- No need for separate thrust housing & bearing.

- Easy alignment (screw directly fits into the vore of gear box)

- Easy to assemble & dismantle.

- Very heavy duty spherical roller thrust bearing is provided.

- Power saving. (you may save up to 20 % power.)

- Less requirement of space.

- For bigger sizes water cooling is provided

- No maintenance required except periodic oil level checking.

- Higher productivity

Features

- Twin Screw Extruder Gearboxes offer the dual shaft counter rotating. The range is available for various center distances

- The gearboxes are available with co-rotating and counter rotating variants

- To work under heavy loading force, the high level dissipation and oil lubrication system are provided. The axial roller type swivel thrust with the thrust bearing coupled in tandem way support the axial thrust

- High torque and high speed output rate

Processing Characteristics of Screw Shaft:

1.Suitable suggestion on material to ensure components performance and extend lifetime of products.

2.Professional technical team can provide surveying and mapping support.

3.All components are finished by CNC machine.

4.Sophisticated quality management system ensure superior quality.

Basic Info.

| Warranty: 1 year | Weight (KG): 500 KG |

| Place of Origin: HangZhou, China |

Gearing Arrangement: helical |

| ratio: 8-20 |

Output Torque: 2*176 |

| standard: JB/T8853-2001 |

Certificate: CE |

| Heat treatment: High-frequency Hardening |

Efficiency: 94%~98%(depends on the transmission stage) |

| Customized support:OEM ODM | Input/output shaft material 40Cr |

| Package: Wooden case |

Mount position: Flange, hollow shaft, CZPT shaft |

| After-sale:Online 24/7 Installation Xihu (West Lake) Dis. | advantage: excellent quality |

| Reduction radio: 3:1 |

Mount Position: Horizontal Foot Mounted Vertical |

| Input Speed: 1500 |

Output Speed: 500 |

Packaging & delivery

|

Packing: wooden case packing |

|

| Port: HangZhou Port |

Applications

X helical gear units for double-screw extruders with parallel drive shafts and the same direction of screw rotation are used mainly in the manufacture of granulates and the refining of raw plastics. Other areas of application include:

- Paint and lacquer industry

- Washing agent industry

- Foodstuff industry (e.g. bread, pasta)

- Animal-feed industry (dog, cat other animal food

Maintenance of the gearbox of the dual-screw extruder

1. The gear box of the dual-screw extruder should be well-ventilated, and the working environment temperature should be within the range of 5-35 °C.

2. Always check the oil quantity of the gear lubricating oil in the box to ensure that the transmission parts in the box are well lubricated.

3. Pay attention to check the bearing parts of the box frequently. The oil temperature of the oil tank of the transmission box should not exceed 70 ºC during operation.

4. The newly put into use gearbox needs to replace the lubricating oil after 250 hours of operation. The oil change time depends on the state of the oil. It is recommended to replace it after 4000-8000 hours of operation or once a year.

5. The gearbox of the dual-screw extruder needs to be regularly maintained and inspected once a year

Operating Process

1. The gear on the input shaft is driven by the motor and starts to rotate.

2. The rotating input gear meshes with other gears inside the gearbox, transmitting power.

3. Different-sized gears within the gearbox are combined to form a gear train. Through continuous meshing and rotation, the high-speed, low-torque power from the input shaft gradually converts into low-speed, high-torque output.

4. The output shaft is connected to the last gear and transfers the output torque to the load.

5. Gear reduction gearboxes typically include lubrication and cooling systems to ensure smooth operation and prevent overheating and damage.

6. Our extruder gearbox converts high-speed, low-torque power into low-speed, high-torque output by changing the size ratios and meshing arrangements of different gears, achieving the function of speed reduction.

Types of Gearboxes:

Based on customer requirements, gear reduction gearboxes can be classified according to the size of the output shaft, center distance of the output shaft, output speed, and torque. Alternatively, we can provide several commonly used types of gearboxes for customers to choose from.

Product Service

|

24-hour Hotline

No matter when and where to call we can find our service to you.

|

Pre-sales Consultation

We have 5 sales people online, and whether you have any question can be solved through online communication. |

After-sales Services

Receive products have any questions about the product, can look for us,we will help you deal with the the first time,to your satisfaction. |

Exhibition

Certificate

Company profile

ZheJiang Arrow Machinery Co., Ltd.is a company specializing in R&D, production, sales, application promotion of food engineering projects. As 1 of the largest scaled food processing equipment &whole plant engineering problem solvers in China, machines served for more than 970 companies, export to 116 countries, area, more than 20 years engineering team, we recognize that quality equals value, aims to create a great future together with global customers.

FAQ

1. Q: How about Arrow Machinery?

R: ZheJiang Arrow Machinery Co., Ltd. is a High-Tech company. Our firm is composed of a strong

team which has substantial experience in R&D, manufacture, technique and sales service and has

specialized in extruder industry for 10 years,leading screw barrel manufacturer in China.

2. Q:What’s Arrow machinery’s capacity?

R:Company is in strict accordance with CE and ISO9001 quality certification system.There are over 200

models of extruders and spare parts.

3. Q:What’s the delivery time?

R:For regular size, we have finished stock and semi-finished stock, 2 weeks max enough

for customized, normally within 20days .

4. Q:How about the gearbox quality and price?

R: top quality in China with competitive price and globle after-sale service

5. Q:what’s the life time and guarantee buy from Arrow machinery ?

R: 3~5years life time for nitriding ones and bimtallic ones will be longer

One year min. Guarantee.

6.Q:Where is Arrow Machinery factory and how to reach there?

R:NO.47 Chengbohu Road, Xihu (West Lake) Dis. District,HangZhou City, China. You can take the train or plane to HangZhou and we can pick you up.

7.Q:How to contact with you?

R:just reply to me if have any question.

| Application: | Motor, Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Cycloidal |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Considerations for Selecting Planetary Gearboxes for Aerospace and Satellite Applications

Selecting planetary gearboxes for aerospace and satellite applications requires careful consideration due to the unique demands of these industries:

- Weight and Size: Aerospace and satellite systems demand lightweight and compact components. Planetary gearboxes with high power density and lightweight materials are preferred to minimize the overall weight and size of the equipment.

- Reliability: Aerospace missions involve critical operations where component failure is not an option. Planetary gearboxes with a proven track record of reliability and durability are essential to ensure mission success.

- High Efficiency: Efficiency is crucial in aerospace applications to optimize power usage and extend the operational life of satellites. Planetary gearboxes with high efficiency ratings contribute to energy conservation.

- Extreme Environments: Aerospace and satellite systems are exposed to harsh conditions such as vacuum, extreme temperatures, and radiation. Planetary gearboxes need to be designed and tested to withstand these conditions without compromising performance.

- Precision and Accuracy: Many aerospace operations require precise positioning and accurate control. Planetary gearboxes with minimal backlash and high precision gear meshing contribute to accurate movements.

- Lubrication: Lubrication plays a vital role in aerospace gearboxes to ensure smooth operation and prevent wear. Gearboxes with efficient lubrication systems or self-lubricating materials are favored.

- Redundancy and Fail-Safe: Some aerospace systems incorporate redundancy to ensure mission success even in case of component failure. Planetary gearboxes with built-in redundancy or fail-safe mechanisms enhance system reliability.

- Integration: Planetary gearboxes need to be seamlessly integrated into the overall design of aerospace and satellite systems. Customization options and compatibility with other components are important factors.

Overall, selecting planetary gearboxes for aerospace and satellite applications involves a comprehensive evaluation of factors related to weight, reliability, efficiency, durability, environmental resistance, precision, and integration to meet the unique demands of these industries.

Impact of Temperature Variations and Environmental Conditions on Planetary Gearbox Performance

The performance of planetary gearboxes can be significantly influenced by temperature variations and environmental conditions. Here’s how these factors impact their operation:

Temperature Variations: Extreme temperature fluctuations can affect the lubrication properties of the gearbox. Cold temperatures can cause the lubricant to thicken, leading to increased friction and reduced efficiency. On the other hand, high temperatures can cause the lubricant to thin out, potentially leading to insufficient lubrication and accelerated wear.

Environmental Contaminants: Planetary gearboxes used in outdoor or industrial environments can be exposed to contaminants such as dust, dirt, moisture, and chemicals. These contaminants can infiltrate the gearbox and degrade the quality of the lubricant. Additionally, abrasive particles can cause wear on gear surfaces, leading to decreased performance and potential damage.

Corrosion: Exposure to moisture, especially in humid or corrosive environments, can lead to corrosion of gearbox components. Corrosion weakens the structural integrity of gears and other components, which can ultimately result in premature failure.

Thermal Expansion: Temperature changes can cause materials to expand and contract. In gearboxes, this can lead to misalignment of gears and improper meshing, causing noise, vibration, and reduced efficiency. Proper consideration of thermal expansion is crucial in gearbox design.

Sealing and Ventilation: To mitigate the impact of temperature and environmental factors, planetary gearboxes need effective sealing to prevent contaminants from entering and to retain the lubricant. Proper ventilation is also essential to prevent pressure build-up inside the gearbox due to temperature changes.

Cooling Systems: In applications where temperature control is critical, cooling systems such as fans or heat exchangers can be incorporated to maintain optimal operating temperatures. This helps prevent overheating and ensures consistent gearbox performance.

Overall, temperature variations and environmental conditions can have a profound impact on the performance and lifespan of planetary gearboxes. Manufacturers and operators need to consider these factors during design, installation, and maintenance to ensure reliable and efficient operation.

Examples of High Torque and Compact Design Applications for Planetary Gearboxes

Planetary gearboxes excel in applications where high torque output and a compact design are essential. Here are some scenarios where these characteristics are crucial:

- Automotive Transmissions: In modern vehicles, planetary gearboxes are used in automatic transmissions to efficiently transmit engine power to the wheels. The compact size of planetary gearboxes allows for integration within the limited space of a vehicle’s transmission housing.

- Robotics: Planetary gearboxes are utilized in robotic arms and joints, where compactness is essential to maintain the robot’s overall size while providing the necessary torque for precise and controlled movement.

- Conveyor Systems: Conveyor belts in industries like material handling and manufacturing often require high torque to move heavy loads. The compact design of planetary gearboxes allows them to be integrated into the conveyor system’s framework.

- Wind Turbines: Wind turbine applications demand high torque to convert low wind speeds into sufficient rotational force for power generation. The compact design of planetary gearboxes helps optimize space within the turbine’s nacelle.

- Construction Machinery: Heavy equipment used in construction, such as excavators and loaders, rely on planetary gearboxes to provide the necessary torque for digging and lifting operations without adding excessive weight to the machinery.

- Marine Propulsion: Planetary gearboxes play a crucial role in marine propulsion systems by efficiently transmitting high torque from the engine to the propeller shaft. The compact design is particularly important in the limited space of a ship’s engine room.

These examples highlight the significance of planetary gearboxes in applications where both high torque output and a compact footprint are vital considerations. Their ability to deliver efficient torque conversion within a small space makes them well-suited for a wide range of industries and machinery.

editor by CX 2023-10-25

China wholesaler CZPT Arrow Various Type of Gearbox for Twin Screw Extruder supplier

Product Description

Overview

Product Description

Wide Selection of Gearbox Products

The gearbox usually adopts a general design scheme, but in special cases, the design scheme of the gearbox can be changed according to the demands of the user, and it can be modified into an industry-specific gearbox. In the design scheme of the gearbox, the parallel shaft, vertical shaft, general box, and various parts can be changed

Advantages

- Absorption of very high torques and axial forces

- No need for separate thrust housing & bearing.

- Easy alignment (screw directly fits into the vore of gear box)

- Easy to assemble & dismantle.

- Very heavy duty spherical roller thrust bearing is provided.

- Power saving. (you may save up to 20 % power.)

- Less requirement of space.

- For bigger sizes water cooling is provided

- No maintenance required except periodic oil level checking.

- Higher productivity

Features

- Twin Screw Extruder Gearboxes offer the dual shaft counter rotating. The range is available for various center distances

- The gearboxes are available with co-rotating and counter rotating variants

- To work under heavy loading force, the high level dissipation and oil lubrication system are provided. The axial roller type swivel thrust with the thrust bearing coupled in tandem way support the axial thrust

- High torque and high speed output rate

Processing Characteristics of Screw Shaft:

1.Suitable suggestion on material to ensure components performance and extend lifetime of products.

2.Professional technical team can provide surveying and mapping support.

3.All components are finished by CNC machine.

4.Sophisticated quality management system ensure superior quality.

Basic Info.

| Warranty: 1 year | Weight (KG): 500 KG |

| Place of Origin: HangZhou, China |

Gearing Arrangement: helical |

| ratio: 8-20 |

Output Torque: 2*176 |

| standard: JB/T8853-2001 |

Certificate: CE |

| Heat treatment: High-frequency Hardening |

Efficiency: 94%~98%(depends on the transmission stage) |

| Customized support:OEM ODM | Input/output shaft material 40Cr |

| Package: Wooden case |

Mount position: Flange, hollow shaft, CZPT shaft |

| After-sale:Online 24/7 Installation Xihu (West Lake) Dis. | advantage: excellent quality |

| Reduction radio: 3:1 |

Mount Position: Horizontal Foot Mounted Vertical |

| Input Speed: 1500 |

Output Speed: 500 |

Packaging & delivery

|

Packing: wooden case packing |

|

| Port: HangZhou Port |

Applications

X helical gear units for double-screw extruders with parallel drive shafts and the same direction of screw rotation are used mainly in the manufacture of granulates and the refining of raw plastics. Other areas of application include:

- Paint and lacquer industry

- Washing agent industry

- Foodstuff industry (e.g. bread, pasta)

- Animal-feed industry (dog, cat other animal food

Maintenance of the gearbox of the dual-screw extruder

1. The gear box of the dual-screw extruder should be well-ventilated, and the working environment temperature should be within the range of 5-35 °C.

2. Always check the oil quantity of the gear lubricating oil in the box to ensure that the transmission parts in the box are well lubricated.

3. Pay attention to check the bearing parts of the box frequently. The oil temperature of the oil tank of the transmission box should not exceed 70 ºC during operation.

4. The newly put into use gearbox needs to replace the lubricating oil after 250 hours of operation. The oil change time depends on the state of the oil. It is recommended to replace it after 4000-8000 hours of operation or once a year.

5. The gearbox of the dual-screw extruder needs to be regularly maintained and inspected once a year

Operating Process

1. The gear on the input shaft is driven by the motor and starts to rotate.

2. The rotating input gear meshes with other gears inside the gearbox, transmitting power.

3. Different-sized gears within the gearbox are combined to form a gear train. Through continuous meshing and rotation, the high-speed, low-torque power from the input shaft gradually converts into low-speed, high-torque output.

4. The output shaft is connected to the last gear and transfers the output torque to the load.

5. Gear reduction gearboxes typically include lubrication and cooling systems to ensure smooth operation and prevent overheating and damage.

6. Our extruder gearbox converts high-speed, low-torque power into low-speed, high-torque output by changing the size ratios and meshing arrangements of different gears, achieving the function of speed reduction.

Types of Gearboxes:

Based on customer requirements, gear reduction gearboxes can be classified according to the size of the output shaft, center distance of the output shaft, output speed, and torque. Alternatively, we can provide several commonly used types of gearboxes for customers to choose from.

Product Service

|

24-hour Hotline

No matter when and where to call we can find our service to you.

|

Pre-sales Consultation

We have 5 sales people online, and whether you have any question can be solved through online communication. |

After-sales Services

Receive products have any questions about the product, can look for us,we will help you deal with the the first time,to your satisfaction. |

Exhibition

Certificate

Company profile

ZheJiang Arrow Machinery Co., Ltd.is a company specializing in R&D, production, sales, application promotion of food engineering projects. As 1 of the largest scaled food processing equipment &whole plant engineering problem solvers in China, machines served for more than 970 companies, export to 116 countries, area, more than 20 years engineering team, we recognize that quality equals value, aims to create a great future together with global customers.

FAQ

1. Q: How about Arrow Machinery?

R: ZheJiang Arrow Machinery Co., Ltd. is a High-Tech company. Our firm is composed of a strong

team which has substantial experience in R&D, manufacture, technique and sales service and has

specialized in extruder industry for 10 years,leading screw barrel manufacturer in China.

2. Q:What’s Arrow machinery’s capacity?

R:Company is in strict accordance with CE and ISO9001 quality certification system.There are over 200

models of extruders and spare parts.

3. Q:What’s the delivery time?

R:For regular size, we have finished stock and semi-finished stock, 2 weeks max enough

for customized, normally within 20days .

4. Q:How about the gearbox quality and price?

R: top quality in China with competitive price and globle after-sale service

5. Q:what’s the life time and guarantee buy from Arrow machinery ?

R: 3~5years life time for nitriding ones and bimtallic ones will be longer

One year min. Guarantee.

6.Q:Where is Arrow Machinery factory and how to reach there?

R:NO.47 Chengbohu Road, Xihu (West Lake) Dis. District,HangZhou City, China. You can take the train or plane to HangZhou and we can pick you up.

7.Q:How to contact with you?

R:just reply to me if have any question.

| Application: | Motor, Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Cycloidal |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Concept of Coaxial and Parallel Shaft Arrangements in Planetary Gearboxes

In planetary gearboxes, the arrangement of shafts plays a crucial role in determining the gearbox’s overall structure and functionality. The two common shaft arrangements are coaxial and parallel configurations:

Coaxial Shaft Arrangement: In a coaxial arrangement, the input shaft and output shaft are positioned along the same axis, resulting in a compact and streamlined design. The planetary gears and other components are aligned concentrically around the central axis, allowing for efficient power transmission and reduced space requirements. Coaxial planetary gearboxes are commonly used in applications where space is limited, and a compact form factor is essential. They are often employed in robotics, automotive systems, and aerospace mechanisms.

Parallel Shaft Arrangement: In a parallel arrangement, the input and output shafts are positioned parallel to each other but on different axes. The planetary gears are aligned in a way that allows the power to be transmitted from the input shaft to the output shaft via a combination of meshing gears. This arrangement allows for a larger gear diameter and higher torque transmission capabilities. Parallel planetary gearboxes are often used in applications requiring high torque and heavy-duty performance, such as industrial machinery, construction equipment, and material handling systems.

The choice between coaxial and parallel shaft arrangements depends on the specific requirements of the application. Coaxial configurations are favored for compactness and efficient power transmission, while parallel configurations excel in handling higher torque and heavy loads. Both arrangements offer distinct advantages and are chosen based on factors like available space, torque demands, load characteristics, and overall system design.

Differences Between Inline and Right-Angle Planetary Gearbox Configurations

Inline and right-angle planetary gearbox configurations are two common designs with distinct characteristics suited for various applications. Here’s a comparison of these configurations:

Inline Planetary Gearbox:

- Configuration: In an inline configuration, the input and output shafts are aligned along the same axis. The sun gear, planetary gears, and ring gear are typically arranged in a straight line.

- Compactness: Inline gearboxes are more compact and have a smaller footprint, making them suitable for applications with limited space.

- Efficiency: Inline configurations tend to have slightly higher efficiency due to the direct alignment of components.

- Output Speed and Torque: Inline gearboxes are better suited for applications that require higher output speeds and lower torque.

- Applications: They are commonly used in robotics, conveyors, printing machines, and other applications where space is a consideration.

Right-Angle Planetary Gearbox:

- Configuration: In a right-angle configuration, the input and output shafts are oriented at a 90-degree angle to each other. This allows for a change in direction of power transmission.

- Space Flexibility: Right-angle gearboxes offer flexibility in arranging components, making them suitable for applications that require changes in direction or where space constraints prevent a straight-line configuration.

- Torque Capacity: Right-angle configurations can handle higher torque loads due to the increased surface area of gear engagement.

- Applications: They are often used in cranes, elevators, conveyor systems, and applications requiring a change in direction.

- Efficiency: Right-angle configurations may have slightly lower efficiency due to increased gear meshing complexity and potential for additional losses.

Choosing between inline and right-angle configurations depends on factors such as available space, required torque and speed, and the need for changes in power transmission direction. Each configuration offers distinct advantages based on the specific needs of the application.

Design Principles and Functions of Planetary Gearboxes

Planetary gearboxes, also known as epicyclic gearboxes, are a type of gearbox that consists of one or more planet gears that revolve around a central sun gear, all contained within an outer ring gear. The design principles and functions of planetary gearboxes are based on this unique arrangement:

- Sun Gear: The sun gear is positioned at the center and is connected to the input shaft. It transmits power from the input source to the planetary gears.

- Planet Gears: Planet gears are small gears that rotate around the sun gear. They are typically mounted on a carrier, which is connected to the output shaft. The interaction between the planet gears and the sun gear creates both speed reduction and torque amplification.

- Ring Gear: The outer ring gear is stationary and surrounds the planet gears. The teeth of the planet gears mesh with the teeth of the ring gear. The ring gear serves as the housing for the planet gears and provides a fixed outer reference point.

- Function: Planetary gearboxes offer various gear reduction ratios by altering the arrangement of the input, output, and planet gears. Depending on the configuration, the sun gear, planet gears, or ring gear can serve as the input, output, or stationary element. This flexibility allows planetary gearboxes to achieve different torque and speed combinations.

- Gear Reduction: In a planetary gearbox, the planet gears rotate while also revolving around the sun gear. This double motion creates multiple gear meshing points, distributing the load and enhancing torque transmission. The output shaft, connected to the planet carrier, rotates at a lower speed and higher torque than the input shaft.

- Torque Amplification: Due to the multiple points of contact between the planet gears and the sun gear, planetary gearboxes can achieve torque amplification. The arrangement of gears allows for load sharing and distribution, leading to efficient torque transmission.

- Compact Size: The compact design of planetary gearboxes, achieved by stacking the gears concentrically, makes them suitable for applications where space is limited.

- Multiple Stages: Planetary gearboxes can be designed with multiple stages, where the output of one stage becomes the input of the next. This arrangement allows for high gear reduction ratios while maintaining a compact size.

- Controlled Motion: By controlling the arrangement of the gears and their rotation, planetary gearboxes can provide different motion outputs, including forward, reverse, and even variable speeds.

Overall, the design principles of planetary gearboxes allow them to provide efficient torque transmission, compact size, high gear reduction, and versatile motion control, making them well-suited for various applications in industries such as automotive, robotics, aerospace, and more.

editor by CX 2023-10-24

China Transmission Geared Motor Unit RV Screw Drive Lifts Stepper Cyclo Cycloidal Extruder Helical Planetary Bevel Worm Speed Variator Gear Reducer Gearbox manufacturer

Merchandise Description

Worm gearbox pace reducer electric motor dc are on sale with high top quality for you

SMRV 571-one hundred fifty worm equipment box with flange and electric motor

SMRV+NMRV Double Phase Arrangement Reduction Gear Box

RV Series Worm Gearbox

worm speed reducer

nmrv worm equipment motor

You can select the 1 type that you need kind these solution introction.

If you have any issue,please speak to me.

HangZhou Sihai Machinery Co.,ltd is a company specialized in research, manufacture and provider of speed gearbox. Ever since institution, we have been persisting in technical innovation, advancing the techonology to our items even though maintaining our rigid quality controls. It is the purpose that our merchandise branding ”Xihu (West Lake) Dis.n” have enjoyed this sort of successful global revenue.

At existing, our business mostly supplies 5 collection items as RV worm gearbox, UDL collection velocity variator,Computer sequence helical equipment device,G3 helical geared motor and SRC helical gearbox. The items are widely utilized in the mechanical products area this sort of as food and beverage,cement,package,chemical and dyeing, rubber and plastic, CNC equipment tool,and so forth.

Our items have been processed ISO 9001 Good quality System Certification and exported to Italy,Spain,Britain,Poland,Turkey.The United states of america and other European countries,make the good track record with our excellent high quality and support.

Clients 1st,buyers satisfaction, outstanding following sale support and incessant innovation are our tenet and motto. We will go all out to provide all the clients with substantial good quality and support.

| To Be Negotiated | 1 Piece (Min. Order) |

###

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Conical – Cylindrical Gear |

| Step: | Single-Step |

###

| Customization: |

Available

|

|---|

| To Be Negotiated | 1 Piece (Min. Order) |

###

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Installation: | Vertical Type |

| Layout: | Coaxial |

| Gear Shape: | Conical – Cylindrical Gear |

| Step: | Single-Step |

###

| Customization: |

Available

|

|---|

Planetary Gearbox

This article will explore the design and applications of a planetary gearbox. The reduction ratio of a planetary gearbox is dependent on the number of teeth in the gears. The ratios of planetary gearboxes are usually lower than those of conventional mechanical transmissions, which are mainly used to drive engines and generators. They are often the best choice for heavy-duty applications. The following are some of the advantages of planetary gearboxes.

planetary gearboxes

Planetary gearboxes work on a similar principle to solar systems. They rotate around a center gear called the sun gear, and two or more outer gears, called planet gears, are connected by a carrier. These gears then drive an output shaft. The arrangement of planet gears is similar to that of the Milky Way’s ring of planets. This arrangement produces the best torque density and stiffness for a gearbox.

As a compact alternative to normal pinion-and-gear reducers, planetary gearing offers many advantages. These characteristics make planetary gearing ideal for a variety of applications, including compactness and low weight. The efficiency of planetary gearing is enhanced by the fact that ninety percent of the input energy is transferred to the output. The gearboxes also have low noise and high torque density. Additionally, their design offers better load distribution, which contributes to a longer service life.

Planetary gears require lubrication. Because they have a smaller footprint than conventional gears, they dissipate heat well. In fact, lubrication can even lower vibration and noise. It’s also important to keep the gears properly lubricated to prevent the wear and tear that comes with use. The lubrication in planetary gears also helps keep them operating properly and reduces wear and tear on the gears.

A planetary gearbox uses multiple planetary parts to achieve the reduction goal. Each gear has an output shaft and a sun gear located in the center. The ring gear is fixed to the machine, while the sun gear is attached to a clamping system. The outer gears are connected to the carrier, and each planetary gear is held together by rings. This arrangement allows the planetary gear to be symmetrical with respect to the input shaft.

The gear ratio of a planetary gearbox is defined by the sun gear’s number of teeth. As the sun gear gets smaller, the ratio of the gear will increase. The ratio range of planetary gears ranges from 3:1 to ten to one. Eventually, however, the sun gear becomes too small, and the torque will fall significantly. The higher the ratio, the less torque the gears can transmit. So, planetary gears are often referred to as “planetary” gears.

Their design

The basic design of a Planetary Gearbox is quite simple. It consists of three interconnecting links, each of which has its own torque. The ring gear is fixed to the frame 0 at O, and the other two are fixed to each other at A and B. The ring gear, meanwhile, is attached to the planet arm 3 at O. All three parts are connected by joints. A free-body diagram is shown in Figure 9.

During the development process, the design team will divide the power to each individual planet into its respective power paths. This distribution will be based on the meshing condition of all gears in the system. Then, the design team will proceed to determine the loads on individual gear meshes. Using this method, it is possible to determine the loads on individual gear meshes and the shape of ring gear housing.

Planetary Gearboxes are made of three gear types. The sun gear is the center, which is connected to the other two gears by an internal tooth ring gear. The planet pinions are arranged in a carrier assembly that sets their spacing. The carrier also incorporates an output shaft. The three components in a Planetary Gearbox mesh with each other, and they rotate together as one. Depending on the application, they may rotate at different speeds or at different times.

The planetary gearbox’s design is unique. In a planetary gearbox, the input gear rotates around the central gear, while the outer gears are arranged around the sun gear. In addition, the ring gear holds the structure together. A carrier connects the outer gears to the output shaft. Ultimately, this gear system transmits high torque. This type of gearbox is ideal for high-speed operations.

The basic design of a Planetary Gearbox consists of multiple contacts that must mesh with each other. A single planet has an integer number of teeth, while the ring has a non-integer number. The teeth of the planets must mesh with each other, as well as the sun. The tooth counts, as well as the planet spacing, play a role in the design. A planetary gearbox must have an integer number of teeth to function properly.

Applications

In addition to the above-mentioned applications, planetary gearing is also used in machine tools, plastic machinery, derrick and dock cranes, and material handling equipments. Further, its application is found in dredging equipment, road-making machinery, sugar crystallizers, and mill drives. While its versatility and efficiency makes it a desirable choice for many industries, its complicated structure and construction make it a complex component.

Among the many benefits of using a planetary gearbox, the ability to transmit greater torque into a controlled space makes it a popular choice for many industries. Moreover, adding additional planet gears increases the torque density. This makes planetary gears suitable for applications requiring high torque. They are also used in electric screwdrivers and turbine engines. However, they are not used in everything. Some of the more common applications are discussed below:

One of the most important features of planetary gearboxes is their compact footprint. They are able to transmit torque while at the same time reducing noise and vibration. In addition to this, they are able to achieve a high speed without sacrificing high-quality performance. The compact footprint of these gears also allows them to be used in high-speed applications. In some cases, a planetary gearbox has sliding sections. Some of these sections are lubricated with oil, while others may require a synthetic gel. Despite these unique features, planetary gears have become common in many industries.

Planetary gears are composed of three components. The sun gear is the input gear, whereas the planet gears are the output gears. They are connected by a carrier. The carrier connects the input shaft with the output shaft. A planetary gearbox can be designed for various requirements, and the type you use will depend on the needs of your application. Its design and performance must meet your application’s needs.

The ratios of planetary gears vary depending on the number of planets. The smaller the sun gear, the greater the ratio. When planetary stages are used alone, the ratio range is 3:1 to 10:1. Higher ratios can be obtained by connecting several planetary stages together in the same ring gear. This method is known as a multi-stage gearbox. However, it can only be used in large gearboxes.

Maintenance

The main component of a planetary gearbox is the planetary gear. It requires regular maintenance and cleaning to remain in top shape. Demand for a longer life span protects all other components of the gearbox. This article will discuss the maintenance and cleaning procedures for planetary gears. After reading this article, you should know how to maintain your planetary gearbox properly. Hopefully, you can enjoy a longer life with your gearbox.

Firstly, it is important to know how to properly lubricate a planetary gearbox. The lubricant is essential as gears that operate at high speeds are subject to high levels of heat and friction. The housing of the planetary gearbox should be constructed to allow the heat to dissipate. The recommended oil is synthetic, and it should be filled between 30 and 50 percent. The lubricant should be changed at least every six months or as needed.

While it may seem unnecessary to replace a planetary gearbox, regular servicing will help it last a long time. A regular inspection will identify a problem and the appropriate repairs are needed. Once the planetary gearbox is full, it will plug with gear oil. To avoid this problem, consider getting the unit repaired instead of replacing the gearbox. This can save you a lot of money over a new planetary gearbox.

Proper lubrication is essential for a long life of your planetary gearbox. Oil change frequency should be based on oil temperature and operating speed. Oil at higher temperatures should be changed more frequently because it loses its molecular structure and cannot form a protective film. After this, oil filter maintenance should be performed every few months. Lastly, the gearbox oil needs to be checked regularly and replaced when necessary.

editor by czh 2023-01-29

in Villavicencio Colombia sales price shop near me near me shop factory supplier Jwell-Single Screw Extruder, Double Screw Extruder, Parallel Twin Screw Extruder manufacturer best Cost Custom Cheap wholesaler

Moreover, all our manufacturing procedures are in compliance with ISO9002 requirements. The team is focused on creating all selection of normal roller chains and sprockets, gears & gearboxes, this kind of as conveyor chain & sprockets , stainless metal chain, agricultural chain and has not just offered its merchandise all above china, but also bought far more than sixty five% merchandise to oversees, which includes Europe, The us, South-east Asia, and it also has set up storage logistics in locations like Europe. In this way, our items have continued to achieve market acceptance and customers gratification in excess of the previous number of a long time. High generation output JWS 60/37 seventy five/38 90/38 one hundred twenty/38 45/33 sixty five/33 75/33 90/33 a hundred and twenty/33 a hundred and fifty/33 EPTT solitary screw extruder/plastic extrusion EPTT

Solution Overview

Single Screw ExtruEPTTfor EPTTPE Pipe

It is extensively employed in the spot of drinking water provide and fuel offer. Feeding EPTT is grooved composition with temperature controller, and straightforward to get higher capacity and stable extrusion. With EPTT BM screw composition, it is ready to divide the EPTTPE substance from reliable to liquid.

High Successful 38 Collection

| Extruder Model |

Screw Dia.(mm) |

L/D Ratio | EPTT (KW) |

Capability (kg/h) |

CEPTTr Top (mm) |

| 60*forty | sixty five | 40 | 90 | 360 | one thousand |

| seventy five*38 | 75 | 38 | 132 | 600 | 1000 |

| 90*38 | 90 | 38 | 250 | 900 | 1150 |

| a hundred and twenty*38 | one hundred twenty | 38 | 315 | 1300 | 1300 |

Traditional 33 Series

| Extruder Product |

Screw Dia.(mm) |

L/D Ratio | EPTT (KW) |

Potential (kg/h) |

CEPTTr Peak (mm) |

| JWS45/33 | forty five | 33 | 18.five/22/thirty | 60-one hundred | a thousand |

| JWS65/33 | 65 | 33 | forty five/75/ninety | 100-250 | a thousand |

| JWS75/33 | 75 | 33 | one hundred ten/132 | 250-350 | one thousand |

| JWS90/33 | 90 | 33 | 160/185 | 450-550 | 1150 |

| JWS120/33 | a hundred and twenty | 33 | 280/315 | 700-900 | 1300 |

| JWS150/33 | a hundred and fifty | 33 | 355/four hundred | 1000-1300 | 1300 |

Functions:

By using the new variety barrier screw layout, this extruEPTThas a large extrusion ability in large RPM with the minimal power usage, and this extruEPTTcan obtain a very good miXiHu (West Lake) Dis.ng influence in the minimal temperature, and this extruEPTTcan management the material shearing to get the ideal and even melt temperature, so that the ripple mark in the internal wall of the big diameter pipe can be prevented.

All kinds of SJZ and SJP extruders that our firm types eEPTTly for creating the PVC pipe and profile, our extruders can guarantee a very good plasticization, higher capability and EPTT electric management, and the EPTT cabinet can be selected by consumer according to their personal requires.

| Screw For Extruder |

| EPTT: 38CrMoAlA |

| Warmth remedy: Nitrited Bimetallic |

| Hardness: HV740-940 |

| Well-known model: EPTTHAILUO |

| Screw Barrel |

| EPTT: 38CrMoAlA |

| Heat treatment method: Nitrited,Bimetallic |

| Hardness: HV940-1100 |

| Well-known brand name: EPTTHAILUO |

SJZ Sequence Counter Conical Twin-Screw Extruder

For production of PVC pipe, profile, Sheet and plate.

For pipe Extrusion

| Extruder Design |

Pace (RPM) |

EPTT (KW) |

Potential (kg/h) |

CEPTTr Top (mm) |

Fat (kg) |

Dimension (M) |

| SJZ45/100 | 45 | fifteen/18.five | one hundred ten | 1050 | 3000 | 3.three*one.2*two.one |

| SJZ50/one hundred and five | forty five | eighteen.five/22 | one hundred twenty five | 1050 | 3000 | 3.six*1.one*2.one |

| SJZ55/one hundred ten | 45 | 22/30 | a hundred and eighty | 1050 | 3500 | three.6*one.1*2.one |