Product Description

Overview

Product Description

Wide Selection of Gearbox Products

The gearbox usually adopts a general design scheme, but in special cases, the design scheme of the gearbox can be changed according to the demands of the user, and it can be modified into an industry-specific gearbox. In the design scheme of the gearbox, the parallel shaft, vertical shaft, general box, and various parts can be changed

Advantages

- Absorption of very high torques and axial forces

- No need for separate thrust housing & bearing.

- Easy alignment (screw directly fits into the vore of gear box)

- Easy to assemble & dismantle.

- Very heavy duty spherical roller thrust bearing is provided.

- Power saving. (you may save up to 20 % power.)

- Less requirement of space.

- For bigger sizes water cooling is provided

- No maintenance required except periodic oil level checking.

- Higher productivity

Features

- Twin Screw Extruder Gearboxes offer the dual shaft counter rotating. The range is available for various center distances

- The gearboxes are available with co-rotating and counter rotating variants

- To work under heavy loading force, the high level dissipation and oil lubrication system are provided. The axial roller type swivel thrust with the thrust bearing coupled in tandem way support the axial thrust

- High torque and high speed output rate

Processing Characteristics of Screw Shaft:

1.Suitable suggestion on material to ensure components performance and extend lifetime of products.

2.Professional technical team can provide surveying and mapping support.

3.All components are finished by CNC machine.

4.Sophisticated quality management system ensure superior quality.

Basic Info.

| Warranty: 1 year | Weight (KG): 500 KG |

| Place of Origin: HangZhou, China |

Gearing Arrangement: helical |

| ratio: 8-20 |

Output Torque: 2*176 |

| standard: JB/T8853-2001 |

Certificate: CE |

| Heat treatment: High-frequency Hardening |

Efficiency: 94%~98%(depends on the transmission stage) |

| Customized support:OEM ODM | Input/output shaft material 40Cr |

| Package: Wooden case |

Mount position: Flange, hollow shaft, CZPT shaft |

| After-sale:Online 24/7 Installation Xihu (West Lake) Dis. | advantage: excellent quality |

| Reduction radio: 3:1 |

Mount Position: Horizontal Foot Mounted Vertical |

| Input Speed: 1500 |

Output Speed: 500 |

Packaging & delivery

|

Packing: wooden case packing |

|

| Port: HangZhou Port |

Applications

X helical gear units for double-screw extruders with parallel drive shafts and the same direction of screw rotation are used mainly in the manufacture of granulates and the refining of raw plastics. Other areas of application include:

- Paint and lacquer industry

- Washing agent industry

- Foodstuff industry (e.g. bread, pasta)

- Animal-feed industry (dog, cat other animal food

Maintenance of the gearbox of the dual-screw extruder

1. The gear box of the dual-screw extruder should be well-ventilated, and the working environment temperature should be within the range of 5-35 °C.

2. Always check the oil quantity of the gear lubricating oil in the box to ensure that the transmission parts in the box are well lubricated.

3. Pay attention to check the bearing parts of the box frequently. The oil temperature of the oil tank of the transmission box should not exceed 70 ºC during operation.

4. The newly put into use gearbox needs to replace the lubricating oil after 250 hours of operation. The oil change time depends on the state of the oil. It is recommended to replace it after 4000-8000 hours of operation or once a year.

5. The gearbox of the dual-screw extruder needs to be regularly maintained and inspected once a year

Operating Process

1. The gear on the input shaft is driven by the motor and starts to rotate.

2. The rotating input gear meshes with other gears inside the gearbox, transmitting power.

3. Different-sized gears within the gearbox are combined to form a gear train. Through continuous meshing and rotation, the high-speed, low-torque power from the input shaft gradually converts into low-speed, high-torque output.

4. The output shaft is connected to the last gear and transfers the output torque to the load.

5. Gear reduction gearboxes typically include lubrication and cooling systems to ensure smooth operation and prevent overheating and damage.

6. Our extruder gearbox converts high-speed, low-torque power into low-speed, high-torque output by changing the size ratios and meshing arrangements of different gears, achieving the function of speed reduction.

Types of Gearboxes:

Based on customer requirements, gear reduction gearboxes can be classified according to the size of the output shaft, center distance of the output shaft, output speed, and torque. Alternatively, we can provide several commonly used types of gearboxes for customers to choose from.

Product Service

|

24-hour Hotline

No matter when and where to call we can find our service to you.

|

Pre-sales Consultation

We have 5 sales people online, and whether you have any question can be solved through online communication. |

After-sales Services

Receive products have any questions about the product, can look for us,we will help you deal with the the first time,to your satisfaction. |

Exhibition

Certificate

Company profile

ZheJiang Arrow Machinery Co., Ltd.is a company specializing in R&D, production, sales, application promotion of food engineering projects. As 1 of the largest scaled food processing equipment &whole plant engineering problem solvers in China, machines served for more than 970 companies, export to 116 countries, area, more than 20 years engineering team, we recognize that quality equals value, aims to create a great future together with global customers.

FAQ

1. Q: How about Arrow Machinery?

R: ZheJiang Arrow Machinery Co., Ltd. is a High-Tech company. Our firm is composed of a strong

team which has substantial experience in R&D, manufacture, technique and sales service and has

specialized in extruder industry for 10 years,leading screw barrel manufacturer in China.

2. Q:What’s Arrow machinery’s capacity?

R:Company is in strict accordance with CE and ISO9001 quality certification system.There are over 200

models of extruders and spare parts.

3. Q:What’s the delivery time?

R:For regular size, we have finished stock and semi-finished stock, 2 weeks max enough

for customized, normally within 20days .

4. Q:How about the gearbox quality and price?

R: top quality in China with competitive price and globle after-sale service

5. Q:what’s the life time and guarantee buy from Arrow machinery ?

R: 3~5years life time for nitriding ones and bimtallic ones will be longer

One year min. Guarantee.

6.Q:Where is Arrow Machinery factory and how to reach there?

R:NO.47 Chengbohu Road, Xihu (West Lake) Dis. District,HangZhou City, China. You can take the train or plane to HangZhou and we can pick you up.

7.Q:How to contact with you?

R:just reply to me if have any question.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Machinery |

|---|---|

| Function: | Distribution Power, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Cycloidal |

| Samples: |

US$ 3600/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Contribution of Planetary Gearboxes to Conveyor Belt Efficiency in Mining Operations

Planetary gearboxes play a crucial role in enhancing the efficiency and performance of conveyor belts in mining operations:

- High Torque Transmission: Planetary gearboxes are capable of transmitting high torque with minimal backlash. This feature ensures that the gearbox efficiently handles the substantial load requirements of conveyor belts used in mining, preventing slippage and ensuring reliable material transportation.

- Compact Design: The compact size of planetary gearboxes allows them to be integrated seamlessly into conveyor systems, optimizing space utilization and allowing for efficient equipment layout in mining environments.

- Variable Speed Control: Planetary gearboxes provide precise speed control and can accommodate various speed requirements of conveyor belts. This versatility allows operators to adjust the conveyor speed to match specific material handling needs.

- High Efficiency: The inherent design of planetary gearboxes minimizes energy losses due to efficient power transmission. This efficiency translates into reduced energy consumption and operational costs over the lifetime of the conveyor system.

- Reliability and Durability: Planetary gearboxes are engineered to withstand demanding conditions often encountered in mining environments, including shock loads, abrasive materials, and harsh weather. Their robust construction ensures reliable operation and minimal downtime.

- Low Maintenance: The durability of planetary gearboxes leads to reduced maintenance requirements. This benefit is particularly valuable in mining operations where minimizing downtime is essential for maintaining high productivity levels.

- Customizability: Planetary gearboxes can be tailored to suit specific conveyor system requirements, including gear ratios, torque ratings, and mounting options. This flexibility allows for optimized system design and performance.

By effectively transmitting power, providing accurate speed control, and offering a compact and robust design, planetary gearboxes significantly enhance the efficiency and reliability of conveyor belts in mining operations. Their ability to handle high loads, operate with low maintenance needs, and withstand harsh conditions contributes to improved productivity and reduced operational costs.

Signs of Wear or Damage in Planetary Gearboxes and Recommended Service

Planetary gearboxes, like any mechanical component, can exhibit signs of wear or damage over time. Recognizing these signs is crucial for timely maintenance to prevent further issues. Here are some common signs of wear or damage in planetary gearboxes:

1. Unusual Noise: Excessive noise, grinding, or whining sounds during operation can indicate worn or misaligned gear teeth. Unusual noise is often a clear indicator that something is wrong within the gearbox.

2. Increased Vibration: Excessive vibration or shaking during operation can result from misalignment, damaged bearings, or worn gears. Vibration can lead to further damage if not addressed promptly.

3. Gear Tooth Wear: Inspect gear teeth for signs of wear, pitting, or chipping. These issues can result from improper lubrication, overload, or other operational factors. Damaged gear teeth can affect the gearbox’s efficiency and performance.

4. Oil Leakage: Leakage of gearbox oil or lubricant can indicate a faulty seal or gasket. Oil leakage not only leads to reduced lubrication but can also cause environmental contamination and further damage to the gearbox components.

5. Temperature Increase: A significant rise in operating temperature can suggest increased friction due to wear or inadequate lubrication. Monitoring temperature changes can help identify potential issues early.

6. Reduced Efficiency: If you notice a decrease in performance, such as decreased torque output or inconsistent speed, it could indicate internal damage to the gearbox components.

7. Abnormal Gear Ratios: If the output speed or torque does not match the expected gear ratio, it could be due to gear wear, misalignment, or other issues affecting the gear engagement.

8. Frequent Maintenance Intervals: If you find that you need to service the gearbox more frequently than usual, it could be a sign that the gearbox is experiencing excessive wear or damage.

When to Service: If any of the above signs are observed, it’s important to address them promptly. Regular maintenance checks are also recommended to detect potential issues early and prevent more significant problems. Scheduled maintenance should include inspections, lubrication checks, and replacement of worn or damaged components.

It’s advisable to consult the gearbox manufacturer’s guidelines for recommended service intervals and practices. Regular maintenance can extend the lifespan of the planetary gearbox and ensure it continues to operate efficiently and reliably.

Contribution of Planetary Gearboxes to Efficient Industrial Automation and Robotics

Planetary gearboxes play a crucial role in enhancing the efficiency of industrial automation and robotics systems by offering several advantages:

1. Compact Design: Planetary gearboxes provide high power density and a compact form factor. This is essential in robotics and automation where space is limited and components need to be tightly integrated.

2. High Torque Density: Planetary gearboxes can achieve high torque output in a compact size, allowing robots and automated systems to handle heavy loads and perform demanding tasks efficiently.

3. Precision and Accuracy: The design of planetary gear systems ensures accurate and precise motion control. This is vital in robotics applications where precise positioning and smooth movement are required for tasks such as pick-and-place operations and assembly.

4. Redundancy: Some planetary gearboxes feature multiple stages and redundant configurations. This provides a level of built-in redundancy, enhancing the reliability of automation systems by allowing continued operation even if one stage fails.

5. Efficiency: Planetary gearboxes are designed for high efficiency, minimizing energy losses and ensuring that the power delivered to the output stage is effectively utilized. This efficiency is crucial for reducing energy consumption and optimizing battery life in robotic applications.

6. Speed Control: Planetary gearboxes allow for precise speed control, enabling robots to perform tasks at varying speeds as needed. This flexibility is essential for tasks that require different motion dynamics or speed profiles.

7. Reduction of Motor Loads: Planetary gearboxes can reduce the load on the motor by providing mechanical advantage through gear reduction. This allows smaller, more efficient motors to be used without sacrificing performance.

8. Shock Absorption: The inherent elasticity of gear teeth in planetary gearboxes can help absorb shocks and impacts, protecting the system components and ensuring smooth operation in dynamic environments.

9. Customization: Planetary gearboxes can be tailored to specific application requirements, including gear ratios, output configurations, and mounting options. This adaptability allows for optimal integration into various automation and robotics setups.

10. Maintenance and Durability: High-quality planetary gearboxes are designed for durability and low maintenance. This is especially important in industrial automation and robotics, where continuous operation and minimal downtime are essential.

Overall, planetary gearboxes contribute significantly to the efficient operation of industrial automation and robotics systems by providing the necessary torque, precision, compactness, and reliability required for these dynamic and demanding applications.

editor by CX 2024-03-30

Best China manufacturer & factory china in Chongjin Dem. People’s Republic of Korea supplier ZLYJ series gearbox rubber screw Extruder Gear box reducer for plastic extrusion machine With high quality best price

With a lot of years’ expertise in these strains, we have been distinguished from other suppliers in China by our rewards in aggressive pricing, on-time delivery, prompt responses, on-hand engineering assist and good after-product sales providers.

Overview

Rapid Specifics

- Applicable Industries:

-

Production Plant

- Pole:

-

one phase two stage a few phase 4 stage

- Ratio:

-

one.twenty five-ninety

-

EPG Team PTO shafts can be used for speeds up to one thousand rpm. The greatest functioning size of the PTO shafts may differ in accordance to the size of the tubes The range of the PTO shafts of RPG Group contains 4 collection , in accordance to the tube form

- Housing Material:

-

Cast Iron

- Substance:

-

20CrMoTi

- Operating temperature:

-

-40~45℃

- Sort:

-

ZLYJ collection gearbox rubber screw Extruder Equipment box reducer for plastic

- Approach:

-

Carburizing, Nitriding , Grinding

- Effectiveness:

-

ninety two%~96%

- Mounting Position:

-

Horizontal,Vertical,Flange

- Shade:

-

Blue,Inexperienced,Gray,Crimson

Packaging & Delivery

-

Direct Time

: -

Quantity(Luggage) 1 – 20 >20 Est. Time(days) eighteen To be negotiated

Online Customization

Solution Description

Professional MANUFACTURE

—— Since 1995

ZLYJ Extruder GearBox

Ever-Power Equipment —— Tianqi Brand industrial gearbox manufacturers

ZLYJ 173/one hundred eighty/two hundred/375 cleaning soap Extruder Gearboxes for plastic extrusion equipment

Major Series Product: R collection helical gear reducer, K series spiral bevel equipment reducer, NGW, P series planetary reducer, H B collection gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical equipment reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloid reducer,ZLYJ Series twin screw extruder gearbox for extruder device, and so forth. In the meantime, map sample processing organization can be undertaken.

Commonly utilised in mining equipment, chemical sector,metal metallurgy, light industry,environmental security, paper creating, printing, lifting transportation, food industry and so on.

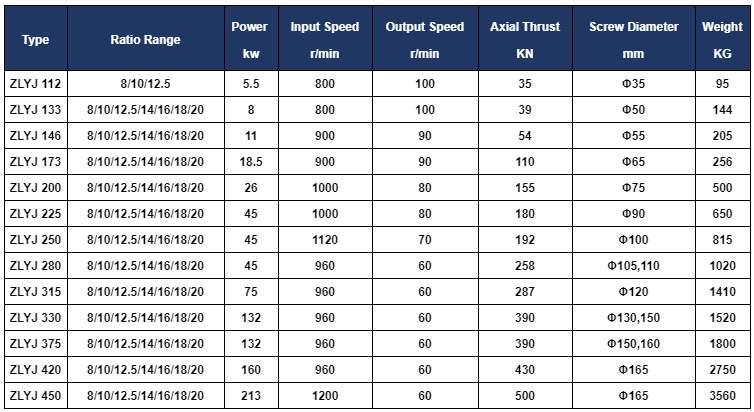

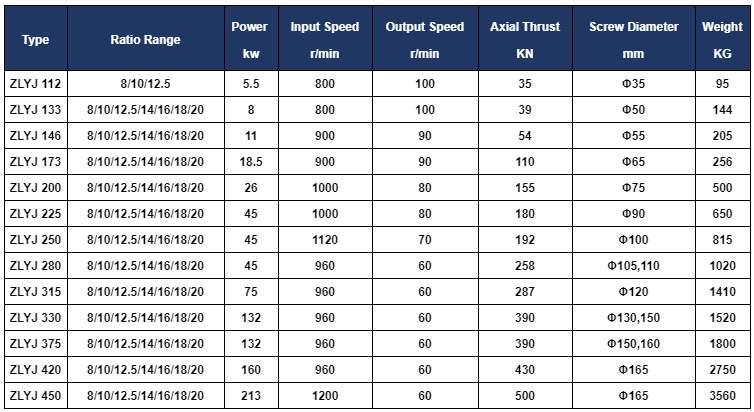

Specification

ZLYJ ZLYJ 173/one hundred eighty/two hundred/375 soap Extruder Gearboxes for plastic extrusion equipment twin screw extruder Gearbox:

Feature:

-

Understood parallel shaft,appropriate-angle shaft modes and horizontal,vertical mounting modes. Using significantly less ingredient areas.

-

Implementing sophisticated grinding method which enhanced the balance and the efficiency of transmit power with In order to find a ideal gearbox for your software from the standard segment, our online SIZING ASSISTANT design and style tool is excellent: dependent on your software information or the wanted motor, a suitable gearbox can be chosen from our portfolio and geometry adjustment executed in a handful of seconds. Upon desire, we can also send you a request for quotation right on the web.reduce noise.H B Bevel helical reduction gearbox fifty:1 for bucket elevators.

-

Input manner: motor linked flange, shaft input.

-

Output method:reliable shaft with flat essential,hollow shaft with flat important,hollow shaft with shrink disk,hollow shaft with spline link, solid shaft with spline relationship, solid shaft with flange.

-

Mounting manner:vertical, horizontal, swing foundation-mounted, torque-arm-mounted.

-

Ratio variety:8~20.

| Variety | ZLYJ133 | ZLYJ146 | ZLYJ173 | ZLYJ200 | ZLYJ225 | ZLYJ280 | ZLYJ315 | ZLYJ330 | ZLYJ420 |

| n | eight | eight | eight | twelve | twelve | 12 | twelve | 12 | 12 |

| d3 | M12 | M12 | M16 | M16 | M20 | M20 | M24 | M24 | M24 |

| centre distance | 205 | 230 | 260 | three hundred | 370 | 400 | 405 | 450 | 580 |

Model choice:

Intently using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is extremely crucial for the life of reducer, and spend interest to whether the greatest torque benefit (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is generally the applicable electricity of the servo versions on the market, the applicability of the reducer is really high, the operating coefficient can be managed earlier mentioned 1.2, but the decision can also be primarily based on their personal wants to choose.Industrial Gearbox Companies H B Collection Substantial rpm Gearbox Reduction with 6: 1 ratio.H B Bevel helical reduction gearbox fifty:1 for bucket elevators.fertilizer spreader gearbox reduction fifty:1 rates. ZLYJ 173/a hundred and eighty/200/375 soap Extruder Gearboxes for plastic extrusion machine.

Technologies

Firm Info

Established in 1995 , HangZhou Ever-Power Machinery is a skilled manufacturer and exporter that is concerned with the style, growth and generation of Gearbox Pace Reducer. We are found in HangZhou of ZheJiang Province, with handy transportation accessibility. With our possess brand “EPG”, all of our products comply with international high quality expectations and are drastically appreciated in a range of various marketplaces all through the globe.

Our company possesses complete machining center, lathe, equipment shaping device, gear milling device, gear grinding equipment and assembling traces. Our nicely-outfitted amenities and outstanding good quality handle all through all levels of creation allows us to assure total consumer satisfaction.

Aside from, In 2005,we attained ISO9001 certification. As a end result of our substantial top quality merchandise and excellent client provider, we have acquired a global income network reaching South America, Saudi Arabia, Vietnam, Pakistan, Philippines, South Africa and other countries and locations.

With abundant export encounter, substantial quality products, competitive rates, good services and in-time supply, we certain that we can meet up with all of your necessity and exceed your expectations. Our feature is bright with new cooperative relationships with companies from all over the globe. We seem forward to speaking with you to future discuss how we can be of support to you.

Chinese Equipment Velocity ReduceUnder the assistance of managerial sense of “Serving agriculture, scoring a good results through quality of products and honesty in business”, our items have been trustworthy by consumers and have gained a greater share of marketplace.r is a mechanical transmission in a lot of fields of the nationwide economy. The merchandise classes protected by the market include all sorts of equipment reducer, planetary equipment reducer and worm gearbox, as nicely as numerous specific transmission products this kind of as velocity growing gadget, velocity control Gadgets, like various kinds of versatile transmission products, this sort of as compound transmission. Goods and solutions in the area of metallurgy, nonferrous metals, coal, building components, ships, drinking water conservancy, electrical power, construction machinery and petrochemical industries.

In all fields of countrywide economic system and nationwide defense industry, gearbox products have a wide selection of programs. Food light-weight business, electrical equipment, building equipment, metallurgy equipment, cement equipment, environmental defense equipment, electronic appliances, road design equipment, h2o conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building supplies machinery, rubber machinery, petroleum machinery and other industries have sturdy need of Reducer products.Industrial Gearbox Makers H B Sequence Large rpm Gearbox Reduction with 6: 1 ratio.H B Bevel helical reduction gearbox 50:1 for bucket elevators.1:forty ratio.3: 1 ratio gearbox.1:30 ratio gearbox.fertilizer spreader gearbox reduction 50:1 rates. ZLYJ 173/a hundred and eighty/two hundred/375 cleaning soap Extruder Gearboxes for plastic extrusion device.

Packaging & Shipping and delivery

FAQ

1.Q:Are you the manufacturing unit or buying and selling firm?

A:We are the Factory, with 23 several years of manufacturing knowledge.

2.Q:Can you customise according to our requirements?

A:Of course, we can design and style nonstandard merchandise in accordance to customer’s drawing and sample.

three.Q:How lengthy is the shipping and delivery date?

A:ten-20 functioning days. Cutomized variety require to according to the quantity.

4.Q:The place is your manufacturing unit?

A:We are in HangZhou of ZheJiang Province, you can get below by higher speed prepare or fly to Jinan.

Welcome to pay a visit to us!

5.Q:What’s your payment terms?

A:TT 30% as deposite, 70% banlance compensated prior to shipping.